Procedure for Traction Pump (P1) Flow Test:

Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately 10

minutes.

11.While holding the traction pedal in full forward, slowly

close flow control valve on tester until pressure gauge

on tester reads 1300 PSI (89.6 bar). As the flow control

valve is being closed, engine speed should decrease to

approximately 2800 RPM (verify engine speed with a

phototac).

1.

2.

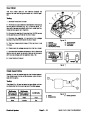

Park machine on a level surface with the attachment

removed. Make sure engine is off.

12.Observe

flow gauge. Tester reading should be

approximately 10 GPM (37.9 LPM). Record test results.

3.

4.

tral position and that traction pedal allows full stroke of

the pump lever (see Operator’s Manual).

Read and follow Precautions for Hydraulic Testing.

Make sure that traction pedal is adjusted to the neu-

13.Release

traction pedal, open flow control valve on

tester and turn engine off.

14.If

1300 PSI (tester pressure), 2800 RPM (engine

speed) or 10 GPM flow cannot be achieved, consider

the following:

WARNING

A. The traction pedal and traction speed may need

adjustment (see Operator’s Manual).

Before jacking up the machine, review and follow

Jacking Instructions in Chapter 1 – Safety.

B. If the engine speed drops excessively (below

2800

engine performance should be evaluated (see

Chapter 3 – Gasoline Engine).

RPM) as the tester flow control valve is closed,

5.

Jack up and support machine with blocks or jack

stands so that all three wheels are off the ground. In this

test, the wheels need to spin freely to allow hydraulic

flow through the traction circuit. Make sure that the park-

ing brake is not applied.

C. If engine speed does not drop and pressure and

flow specifications are not met, the hydrostat needs

to be repaired or replaced as necessary.

IMPORTANT: Make sure to thoroughly clean around

all hydraulic connections that will be disassembled.

15.If specifications are met and a traction circuit prob-

lem exists, check wheel motor efficiency (see Wheel

Motor Efficiency Test in this section).

6.

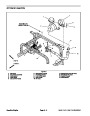

Disconnect hydraulic hose from hydraulic tube lead-

ing to the front wheel motor lower port to allow hydraulic

tester (flow meter) installation (Fig. 22).

16.When testing is complete, lower wheels to the

ground. Remove hydraulic tester and reconnect hydrau-

lic hose to hydraulic tube.

7.

Install hydraulic tester (flow meter) between discon-

nected hose and tube. Make sure that tester flow arrow

points from the hose and into the tube. Make sure the

flow control valve on the tester is fully open.

17.Make sure hydraulic tank is full (see Operator’s

Manual).

8.

at low idle speed. Check for hydraulic leakage and cor-

rect before proceeding with test.

After installing hydraulic tester, start engine and run

9.

Operate engine at full speed (3400 RPM).

CAUTION

1

Use extreme caution when taking gauge read-

ings. The wheels off the ground will be spinning.

2

10.Sit

in the operator seat and slowly push traction ped-

al to the full forward position.

Figure 22

1.

Tube to lower motor port

2.

Hydraulic hose

Sand Pro & Infield Pro 3040/5040

Page 4 – 27

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro 3040, Toro 5040 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)