Procedure for Engine Cooling Fan Circuit Test

Make sure hydraulic oil is at normal operating tem-

1.

perature by operating the machine under load for

approximately ten (10) minutes. Make sure the hydrau-

lic tank is full.

2

2.

lowered and off. Make sure engine is off and the parking

brake is applied. Raise and support hood.

Parkmachineonalevelsurfacewiththecuttingdeck

1

CAUTION

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

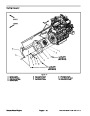

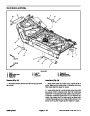

Figure 48

1.

Fan drive manifold

2.

Test port G1

3.

48).

hydraulic hose attached to test port on top of manifold

(Fig. 49).

Raise seat to gain access to fan drive manifold (Fig.

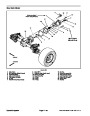

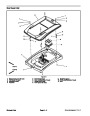

Connect a5,000 PSI (345 bar) pressure gauge with

3

RIGHT

FRONT

2

4.

at idle speed. Check for hydraulic leakage at gauge

location and correct before proceeding with test.

After installing pressure gauge, start engine and run

5.

(2870

Move throttle so engine is running at high idle speed

RPM).

1

6.

While monitoring the pressure gauge and using a

phototac to identify the cooling fan speed, disconnect

the wire harness connector (white/green and black

wires)fromthePRVsolenoidonfandrivemanifold.Both

fan speed and pressure should increase and stabilize

after the solenoid is disconnected.

Figure 49

1.

2.

Fan drive manifold

PRV solenoid

3.

Test port G1

PRESSURE GAUGE READING TO BE approxi-

mately 3000 PSI (207 bar).

PHOTOTAC READING TO BE: fan speed should be

at least 2800 RPM.

7.

8.

bar) but fan speed is low, consider that the fan motor is

worn or damaged. If pressure and fan speed are both

low, consider that the gear pump is worn or damaged

(see Engine Cooling Fan Circuit Gear Pump Flow Test).

Stop engine and record test results.

If pressure rises to approximately 3000 PSI (207

NOTE: Ifpressure and fan speed are bothlow andgear

pump flow proves tobe correct, suspect thatseals infan

drive manifold are leaking or faulty (see Fan Drive Man-

ifold Service in the Service and Repairs section of this

chapter).

9.

and reconnect wire harness to PRV solenoid.

When testing is complete, remove pressure gauge

Groundsmaster 4100--D/4110--D

Page 4 -- 67

Hydraulic System

Product Specification

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 10177SL, Toro Groundsmaster 30447, Toro Groundsmaster 30449, Toro Groundsmaster 4100, Toro Groundsmaster 4110 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |