15.Connect

16.Remove

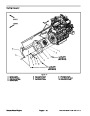

screws securing the engine mounts to the engine sup-

ports.

hoist or lift to the lift tabs on engine.

2

6

flange nuts, rebound washers and cap

1

3

7

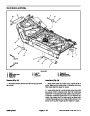

CAUTION

One person should operate lift or hoist while

another person guides the engine out of the ma-

chine.

4

5

IMPORTANT: Make sure to not damage the engine,

fuel hoses, hydraulic lines, electrical harness or

other components while removing the engine.

17.Slowly

remove engine assembly from the machine.

18.If

necessary,remove engine mounts fromtheengine

using Figure 10 as a guide.

Engine Installation (Fig. 10)

Figure 16

1.

Make sure that all parts removed from the engine

during maintenance or rebuilding are installed to theen-

gine.

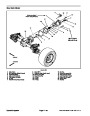

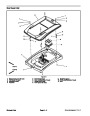

1.

2.

3.

4.

Washer reservoir

Reservoir mount

Carriage screw (3 used)

Washer (3 used)

5.

6.

7.

Nut (3 used)

Flange head screw

Exhaust mount

2.

Ifremoved,installengine mounts totheengineusing

Figure 10 as a guide.

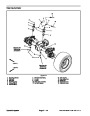

7.

Install cooling fan motor and fan assembly (Fig. 15).

3.

Connect hoist or lift to the engine lift tabs.

A. Carefullypositionfanmotor,fanandmotorbrack-

et assembly to radiator.

CAUTION

B. Secure fan motor bracket to radiator with six (6)

cap screws and flange nuts.

One person should operate lift or hoist while

another person guides the engine into the ma-

chine.

C. Remove caps and plugs that were placed in

hosesandfittingsduringremovaltopreventcontam-

ination.

IMPORTANT: Make sure to not damage the engine,

fuel hoses, hydraulic lines, electrical harness or

other parts while installing the engine.

D. Connect hydraulic hoses to cooling fan motor

(see Hydraulic Hose and Tube Installation in the

GeneralInformationsectionofChapter4 -- Hydraulic

System).

4.

Carefully lower engine into the machine.

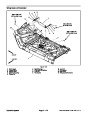

8.

Position upper radiator shroud and coolant reservoir

5.

pumpinputshaft.Secureenginetoenginesupportswith

cap screws, rebound washers and flange nuts.

Align engine to the engine supports and hydraulic

withbrackettotheradiator.Secureshroudandreservoir

bracket to the radiator and lower radiator bracket with

removed fasteners (seeRadiator Installation in thissec-

tion). Make sure thatclearance between shroud and fan

is at least 0.180” (4.6 mm) at all points.

6.

Pump Assembly Installation in the Service and Repairs

section of Chapter 4 -- Hydraulic System).

Secure hydraulic pump assembly to engine (see

Groundsmaster 4100--D/4110--D

Page 3 -- 15

Kubota Diesel Engine

Product Specification

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 10177SL, Toro Groundsmaster 30447, Toro Groundsmaster 30449, Toro Groundsmaster 4100, Toro Groundsmaster 4110 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |