8.

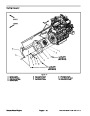

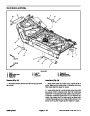

(Fig. 13).

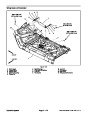

Disconnect fuel supply hose from injection pump

13.Support hydraulic pump assembly. Remove fasten-

ers that secure pump assembly to engine (see Pump

Assembly Removal in the Service and Repairs section

of Chapter 4 -- Hydraulic System).

9.

Remove throttle cable fromengine (Figs.13and14):

A. Remove lock nut that secures throttle cable swiv-

el to speed control lever.

14.Make

fuel lines or hydraulic hoses to the engine are removed.

sure all cable ties securing the wiring harness,

B. Loosen cable clamp and remove throttle cable

from under clamp.

11

10

C. Position throttle cable away from the engine.

10.Remove

fasteners that secure the upper radiator

shroud to the lower shroud and radiator (see Radiator

Removal in this section). Position coolant reservoir and

bracket away from the radiator. Remove upper radiator

shroud from machine.

1

3

9

8

6

11.

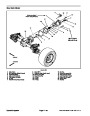

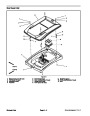

Remove cooling fan motor and fan assembly (Fig.

4

15).

7

5

A. To prevent contamination of hydraulic system,

thoroughly clean exterior of fan motor and fittings.

2

B. Disconnect hydraulic hoses from cooling fan mo-

tor.Putcaps orplugs onfittings andhoses toprevent

contamination. Label hydraulic hoses for proper as-

sembly.

Figure 14

7.

8.

9.

10. Cable swivel

11. Cable stop

1.

2.

3.

4.

5.

6.

Lock nut

Cable clamp

Spring washer (2 used)

Lock nut

Throttle cable

Cable support

Lock nut

C. Remove six (6) cap screws and flange nuts that

secure fan motor bracket to radiator.

Washer head screw

Cap screw (2 used)

D. Carefully remove cooling fan motor, fan and mo-

tor bracket assembly from machine.

6

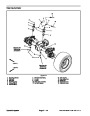

12.On

Groundsmaster 4110--D machines:

A. Remove windshield washer reservoir from reser-

voir mount on engine (Fig. 16). Position reservoir

away from engine. Do not remove reservoir mount

from engine.

3

4

5

1

B. Remove air conditioning compressor from brack-

ets (see Air Conditioning Compressor Removal in

theServiceandRepairssectionofChapter9 -- Oper-

ator Cab). Position compressor away from engine

taking care to not damage compressor or hoses.

Support compressor to make sure it will not fall dur-

ing engine removal.

2

C. Disconnect coolant hose from fitting on engine

water flange.

Figure 15

1.

2.

3.

Fan

Fan motor bracket

Fan motor

4.

5.

6.

Cap screw (6 used)

Flange nut (6 used)

Radiator

IMPORTANT: The hydraulic pump assembly can re-

main in machine during engine removal. To prevent

pump from shifting or falling, make sure to support

pump assembly before mounting fasteners are re-

moved.

Kubota Diesel Engine

Page 3 -- 14

Groundsmaster 4100--D/4110--D

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 10177SL, Toro Groundsmaster 30447, Toro Groundsmaster 30449, Toro Groundsmaster 4100, Toro Groundsmaster 4110 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)