Procedure for Cutting Deck Gear Pump Flow Test

IMPORTANT: Do not fully restrict oil flow through

tester. In this test, the flow tester is positioned be-

fore the relief valve. Pump damage can occur if the

oil flow is fully restricted.

NOTE: Overaperiodoftime,thegearsandwearplates

in the gear pump can wear. A worn pump will by--pass

oilandmakethepumplessefficient.Eventually,enough

oillosswilloccurtocausethecuttingdeckmotorstostall

under heavy cutting conditions. Continued operation

with a worn, inefficient pump can generate excessive

heat and cause damage to the seals and other compo-

nents in the hydraulic system.

7. Watch pressure gauge carefully while slowly closing

the tester flow control valve until 2000 PSI is obtained.

Verify with aphototac thattheengine speedis still2870

RPM.

NOTE: If engine speed drops below 2870 RPM, pump

IMPORTANT: Mow circuit flow for the Groundsmas-

ter 4100/4110 is approximately 16 GPM (61 LPM).

Use 40 GPM Hydraulic Tester #AT40002 (pressure

and flow) for this test (see Special Tools in this

chapter).

flow will decrease.

8.

Foragearpumpingoodcondition,pumpflowshould

be approximately 16 GPM (61 LPM). Fully open tester

flow control valve and shut off engine. Record test re-

sults.

1.

Make sure hydraulic oil is at normal operating tem-

9.

If measured flow is less than 14 GPM (53 LPM) or

perature by operating the machine under load for

approximately ten (10) minutes. Make sure the hydrau-

lic tank is full.

if a pressure of 2000 PSI cannot be obtained, check for

restriction in the pump intake line. If line is not restricted,

remove gear pump and repair or replace as necessary.

2.

lowered and off. Make sure engine is off and the parking

brake is engaged.

Parkmachineonalevelsurfacewiththecuttingdeck

10.When

hose kitfrom manifold portandmachine hydraulic hose.

Reconnect machine hose to the manifold.

testing is complete, disconnect tester and

11.

tion if required.

Repeat test for second cutting deck gear pump sec-

CAUTION

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

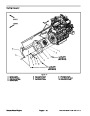

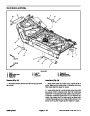

TO OIL COOLER

RIGHT

FRONT

1

3.

Locate PTO control manifold for gear pump section

to be tested (front or LH manifold). Thoroughly clean

junction of manifold fitting and hydraulic hose at PTO

manifold port (P1) (Fig. 43). Disconnect hydraulic hose

from port (P1) fitting.

3

4

2

4.

Install 40 GPM Hydraulic Tester #AT40002 (pres-

sure and flow) in series with the disconnected hose and

hydraulic manifold port(P1).Use hydraulic hose kit(see

Special Tools in this chapter) to connect tester to ma-

chine. Make sure the flow control valve on the tester

is fully open.

Figure 43

1.

2.

Center deck manifold

Hyd. hose to front P1

3.

4.

LH wing deck manifold

Hyd. hose to side P1

5.

After installing tester, start engine and run at idle

speed. Check for hydraulic leakage at tester location

and correct before proceeding with test.

6.

(2870

Move throttle so engine is running at high idle speed

RPM). Do not engage the cutting deck.

Groundsmaster 4100--D/4110--D

Page 4 -- 57

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 10177SL, Toro Groundsmaster 30447, Toro Groundsmaster 30449, Toro Groundsmaster 4100, Toro Groundsmaster 4110 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)