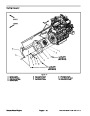

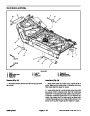

Blade Spindle Service

DRIVEN SPINDLE

7

8

1

2

3

9

10

12

11

14

130

(176

to 150 ft--lb

to 203 N--m)

4

13

DRIVE SPINDLE

15

1

5

2

9

8

16

17

6

4

Figure 16

1.

2.

3.

4.

5.

6.

Lock nut

7.

8.

9.

10. Outer bearing spacer

11. Inner bearing spacer

12. Spacer ring

O--ring

Oil seal

Bearing cup and cone

13. Snap ring

Flat washer

14. Grease fitting

15. Spindle housing

16. Spindle shaft spacer

17. Spindle shaft

Driven pulley

Spindle shaft

Drive pulley (single shown)

Hydraulic motor mount

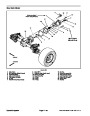

Disassembly (Fig. 16)

Loosen and remove lock nut from top of spindle

shaft. Remove hardened washer and pulley from

spindle. For drive spindle, remove hydraulic motor

mount.

Assembly (Fig. 16)

1.

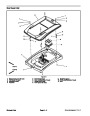

NOTE: Areplacement spindle bearing set contains two

(2) bearings, a spacer ring and a large snap ring (items

1, 2 and 3 in Fig. 17). These parts cannot be purchased

separately. Also, do not mix bearing set components

from one deck spindle to another.

2.

Remove the spindle shaft from the spindle housing

whichmayrequiretheuseofanarborpress.Thespindle

shaft spacer should remain on the spindle shaft as the

shaft is being removed.

NOTE: A replacement bearing spacer set includes the

inner spacer and outer spacer (items 4 and 5 in Fig. 17).

Do not mix bearing spacers from one deck spindle to

another.

3.

Carefully remove oil seals from spindle housing tak-

ing care to not damage seal bore in housing.

IMPORTANT: If new bearings are installed into a

usedspindlehousing,itmaynotbenecessarytore-

place the original large snap ring. If the original

snap ring is in good condition with no evidence of

damage (e.g. spun bearing), leave the snap ring in

the housing and discard the snap ring that comes

with the new bearings. Ifthe large snap ring isfound

to be damaged, replace the snap ring.

4.

spacer ring to drop out of the spindle housing (Fig. 17).

Allow the bearing cones, inner bearing spacer and

5.

cups and the outer bearing spacer from the housing.

Using an arbor press, remove both of the bearing

6.

The large snap ring can remain inside the spindle

housing. Removal of this snap ring is very difficult.

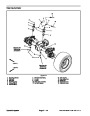

1.

Iflargesnapringwasremovedfromspindlehousing,

install snap ring into housing groove. Make sure snap

ring is fully seated in housing groove.

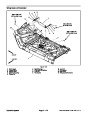

Cutting Deck

Page 8 -- 18

Groundsmaster 4100--D/4110--D

Product Specification

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 10177SL, Toro Groundsmaster 30447, Toro Groundsmaster 30449, Toro Groundsmaster 4100, Toro Groundsmaster 4110 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |