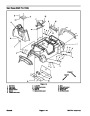

Removal (Fig. 24)

Park machine on a level surface, stop engine, en-

1.

gage parking brake, and remove key from the ignition

switch.

2.

Drain oil from transaxle (see Operator’s Manual).

1

3.

Disconnect negative (–) cable from battery first and

2

then positive (+) cable.

Block front wheels. Jack–up rear of machine and se-

4.

cure machine with jack stands or blocks so transaxle

can be removed by sliding out under rear of machine

(see Jacking Instructions in Operator’s Manual).

5.

harness (Fig. 25).

Unplug speed sensor connector from machine wire

Figure 25

1.

Speed sensor connector

2.

Suction hose

6.

Label shift cables to ease reassembly. Loosen shift

cable jam nuts at cable mount (Fig. 26). Remove cotter

pin and clevis pin that attach shift cable ends to trans-

axle shift arm levers. Pull shift cables free from mount.

3

1

7.

8.

Drain oil from transaxle (see Operator’s Manual).

Disconnect hydraulic return hose from top of trans-

2

2

axle (Fig. 26). Locate, remove, and discard hose o–ring.

9.

Locate, remove, and discard suction hose o–ring. Posi-

tion suction hose away from transaxle.

Disconnect suction hose from transaxle (Fig. 25).

10.Put

caps or plugs on all open hoses and fittings to

1

prevent contamination.

11.

Remove two (2) R–clamps that secure LH parking

Figure 26

brake cable to front transaxle mount.

1.

2.

Shift cable jam nut

Clevis pin

3.

Hydraulic return hose

12.Remove

the straps securing driveshaft bearing

cross to the end yoke at both rear wheel hubs.

13.Loosen

and remove cap screws, hardened washers,

and lock nuts that secure driveshafts (both right and left

sides) to transaxle axle shafts (Fig. 27). Remove both

driveshafts from machine.

14.Loosen

and remove cap screws and flange nuts that

secure universal joint of transaxle driveshaft to input

shaft of transaxle (Fig. 28). Disconnect driveshaft from

transaxle input shaft.

1

2

15.Support

transaxle to prevent it from shifting or falling.

3

Remove four flange nuts that secure transaxle mounts

to machine frame. Lower transaxle with mounts from

machine.

Figure 27

16.If

mount, and transaxle strap mounts from transaxle.

required, remove front transaxle mount, shift cable

1.

2.

Cap screw w/washer

Driveshaft (LH)

3.

Driveshaft (RH)

17.Remove

oil strainer from transaxle. Locate, remove,

and discard strainer o–ring.

Multi Pro 1200/1250

Page 7 – 27

Drive Train

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Multi Pro 1200, Toro Multi Pro 1250 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)