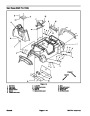

Removal (Fig. 7)

Park machine on a level surface, stop engine, and

1.

remove key from the ignition switch. Chock wheels to

keep the machine from moving.

4

1

2

2.

Disconnect negative (–) and then positive (+) battery

cables at the battery.

3.

tem (see Exhaust System Removal).

Remove muffler/tailpipe section of the exhaust sys-

5

3

4.

9).

Remove accelerator cable from engine (Fig. 8 and

Figure 8

4.

5.

1.

2.

3.

Acceleratorcable

Cable ball joint

Cable jam nut

Choke cable

Choke cable clamp

A. Slide the sleeve back on the cable ball joint and lift

accelerator cable from the ball stud.

B. Loosen one of the two cable jam nuts that se-

cures accelerator cable to control bracket.

5

4

3

6

C. Remove accelerator cable from the engine speed

control bracket and position away from the engine.

2

5.

bracket (Fig. 8 and 9).

Remove choke cable from the engine speed control

6

7

1

6.

Gaining access from under operator seat, loosen

two (2) flange head screws and flange nuts that secure

oil filter adapter to right hand frame rail (Fig. 10). Slide

adapter with oil filter away from frame.

8

7.

Disconnect engine electrical connections. Position

unplugged wires away from engine.

A. Unplug engine wire harness from machine har-

ness.

B. Remove nut on starter solenoid stud. Remove

two red wires and positive (+) battery cable from so-

lenoid stud.

Figure 9

1.

2.

3.

4.

Acceleratorcable

Cable ball joint

Choke cable

5.

6.

7.

8.

Cap screw

Ball joint jam nut

Speed control bracket

Hex nut

C. Remove flange head screw and nut under starter

motor that secures engine and negative (–) cable to

engine mounting plate (Fig. 11).

Choke cable clamp

1

8.

Remove transaxle drive shaft from pump drive gear-

box (see Pump Drive Gearbox in the Service and Re-

pairs Section of Chapter 7 – Drive Train). Locate and

retrieve key.

2

9.

Disconnect spray pump coupler from pump drive

electric clutch. Unplug clutch wiring connector from ma-

chine harness (see Pump Drive Electric Clutch in the

Service and Repairs Section of Chapter 6 – Spray Sys-

tem).

10.If

the mounting plate is being removed from ma-

Figure 10

chine, clamp fuel line at the fuel tank outlet to prevent

fuel leakage. Disconnect fuel hose from fuel pump on

engine and pull fuel line from R–clamps on mount plate.

Position disconnected fuel line away from engine.

1.

Oil filter adapter

2.

RH frame rail

Multi Pro 1200/1250

Page 3 – 11

Kohler Gasoline Engine

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Multi Pro 1200, Toro Multi Pro 1250 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)