CAUTION

1

Rotate steering wheel to relieve hydraulic sys-

tem pressure and avoid injury from pressurized

hydraulic oil.

3

2

4

11.

If the mounting plate assembly is being removed

from machine, label all hydraulic connections for reas-

sembly purposes. Clean hydraulic hose ends prior to

disconnecting the hoses. Remove hydraulic hoses from

steering pump.

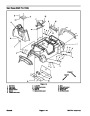

Figure 11

12.Remove

chine (Fig. 7 and 11):

engine mounting plate assembly from ma-

1.

2.

Frame

3.

4.

Engine mount

Negative battery cable

Engine support strap

A. Support the engine mounting plate assembly

from below to prevent it from falling.

B. Remove four (4) cap screws and flange nuts that

secure the engine support straps to the frame.

2

IMPORTANT: Make sure not to damage the en-

gine, fuel hoses, hydraulic lines, electrical har-

ness, or other parts while lowering the engine

mounting plate assembly.

3

1

C. Carefully lower engine mounting plate assembly

from machine.

Installation (Fig. 7)

1.

Place machine on a level surface with key removed

from the ignition switch. Chock wheels to keep the ma-

chine from moving.

2

2.

Reinstall engine mounting plate assembly to ma-

chine (Fig. 7 and 11):

Figure 12

1.

2.

Engine support strap

3.

Engine mount tube

A. Make sure that engine mounts are assembled to

mounting straps correctly (Fig. 12). Position engine

mounting plate assembly under machine.

Engine mount cushion

4.

Connect spray pump coupler to pump drive electric

clutch. Plug clutch wiring connector into machine har-

ness (see Pump Drive Electric Clutch in the Service and

Repairs Section of Chapter 6 – Spray System).

IMPORTANT: Make sure not to damage the en-

gine, fuel hoses, hydraulic lines, electrical har-

ness, or other parts while raising the engine

mounting plate assembly.

5.

Reconnect engine electrical connections.

B. Carefully raise engine mounting plate assembly

to machine frame.

A. Pull wiring harness into position keeping harness

away from any moving components.

C. Secure engine mounting plate assembly to frame

with four (4) cap screws and flange nuts.

B. Secure two (2) red wires and positive (+) battery

cable to starter solenoid stud with nut.

3.

Position key in pump drive gearbox shaft. Install

C. Connect engine wire harness to main wire har-

ness.

transaxle drive shaft to pump drive gearbox (see Pump

Drive Gearbox in the Service and Repairs Section of

Chapter 7 – Drive Train).

D. From below, install flange head screw and nut un-

der starter motor that secures engine and negative

(–)

cable (Fig. 11).

Kohler Gasoline Engine

Multi Pro 1200/1250

Page 3 – 12

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Multi Pro 1200, Toro Multi Pro 1250 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)