NOTE: The ports on the hydraulic manifold are marked

for easy identification of components. Example: FC1 is

the flow control valve and P1 is the gear pump connec-

tion port (see Hydraulic Schematics to identify the func-

tion of the hydraulic lines and cartridge valves at each

port location).

5. Cleaning cartridge valves:

A. For non--solenoid operated valves:

Submerge valve in clean mineral spirits to flush out

contamination. If valve design allows, use a probe to

push the internal spool in and out 20 to 30 times to

flush out contamination. Particles as fine as talcum

powder can affect the operation of high pressure hy-

draulic valves. Clean and dry cartridge with com-

pressed air.

NOTE: ThehydraulicmanifoldshowninFigure55uses

several zero leak plugs. These plugs have a tapered

sealing surface on the plug head that is designed to re-

sist vibration induced plug loosening. The zero leak

plugs also have an O--ring to provide a secondary seal.

If zero leak plug removal is necessary, lightly rap the

plug head using a punch and hammer before using an

allen wrench to remove the plug: the impact will allow

plug removal with less chance of damage to the socket

headoftheplug.Wheninstallingplugsintothemanifold,

torque plugs to the values identified in Figure 55.

B. For solenoid operated valves:

Temporarily install solenoid on cartridge valve and

connecta12voltpowersourcetothesolenoid.While

energized, flush out any contamination with a non-

flammable aerosol brake cleaner. De-energize the

solenoid. Repeat the flush while energized proce-

dure 5 or 6 times. Particles as fine as talcum powder

can affect the operation of high pressure hydraulic

valves. Remove solenoid from cartridge.

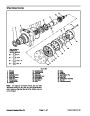

Solenoid Operated, Relief and Logic Control Car-

tridge Valves (Fig. 55)

6.

Reinstall the cartridge valve into the manifold:

1.

cartridge valve and seal kit.

Make sure the manifold is clean before removing the

A. Lubricate new O-rings and backup rings of seal

kit with clean hydraulic oil and install on cartridge.

The O-rings and backup rings must be arranged

properly on the cartridge valve for proper operation

and sealing.

2.

move nutsecuring solenoid tothecartridge valve. Care-

fully slide solenoid off the valve.

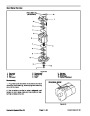

If solenoid valve is to be removed from manifold, re-

IMPORTANT: Usecarewhenremovingthecartridge

valve. Slight bending or distortion of the stem tube

can cause binding and malfunction. Make sure that

deep well socket fully engages the valve base.

IMPORTANT: Use care when installing the car-

tridge valve. Slight bending or distortion of the

stem tube can cause binding and malfunction.

Make sure that deep well socket fully engages

the valve base.

3.

Make sure manifold is clean before removing the

cartridge valve. Remove cartridge valve from manifold

with a deep well socket. Note location of O--rings and

backup rings on valve. Remove and discard removed

seal kit.

B. Lubricate threads on cartridge valve with clean

hydraulic oil. Thread cartridge valve carefully into

correct manifold port. The valve should go in easily

without binding.

4.

for damage to sealing surfaces, damaged threads, and

contamination.

Visuallyinspectthemanifoldportandcartridgevalve

C. Torque cartridge valve using a deep well socket

to specification shown in Figure 55.

7.

For solenoid valve, slide solenoid coil onto the car-

A. Contamination may cause valves to stick or hang

up.Contaminationcanbecomelodgedinsmallvalve

orifices or seal areas causing valve malfunction.

tridgevalve.Installandtorquenutto60in--lb(6.7N--m).

8.

If problems still exist, remove valve and clean again

or replace valve.

B. If valve sealing surfaces appear pitted or dam-

aged, the hydraulic system may be overheating or

there may be water in the system.

CAUTION

Use eye protection such as goggles when using

compressed air.

Greensmaster 3150

Page 4 -- 83

Hydraulic System (Rev. E)

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Greensmaster 3150 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(1 votes, average: 2 out of 2)

Lawn and Garden readers have rated Toro 03113SL Rev E Greensmaster 3150 Service Manual 2.0 out of 2.0 based on 1 product reviews. Safety switches not working