3.

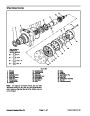

(Fig. 46) for the following:

Inspect drive gear, idler gear and bearing blocks

5. Lubricate gear faces and bearing surfaces of drive

gear, idler gear,and bearing blocks. Carefully assemble

bearing blocks and gears noting identification marks

made during disassembly.

A. Gear shafts should be free of rough surfaces and

excessive wear at bushing points and sealing areas.

Scoring, rough surfaces, or wear on gear shafts indi-

cates need for replacement.

6. Position the motor body on its side. Carefully slide

bearing block and gear assembly into the body cavity

using identification marks made during disassembly.

B. Gear teeth should be free of excessive scoring

and wear. Any broken or nicked gear teeth must be

replaced.

7. Remove any excess lubrication from mating sur-

faces of body, rear cover, and front flange. Make sure

that these surfaces are clean and dry.

C. Inspect gear face edge for sharpness. Sharp

edges of gears will mill into bearing blocks and, thus,

must be replaced.

8. Install dowel pins in body.

IMPORTANT: Do not dislodge O--rings, pressure

seals, or back--up rings during final assembly.

D. Bearing areas of bearing blocks should not have

excessive wear or scoring.

9.

Gently slide the rear cover onto the assembly using

E. Face of bearing blocks that are in contact with

gears should be free of wear, roughness or scoring.

marker or scribe mark for proper location. Firm hand

pressure should be sufficient to engage the dowel pins.

4.

wear.

Inspect front flange and rear cover for damage or

10.Position themotorwithrearcover downwards. Care-

fullyslidethefrontflangeontotheassembly usingmark-

er or scribe mark for proper location.

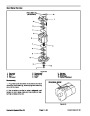

Reassembly

11.

Install the four (4) cap screws and hand tighten.

NOTE: Whenreassemblingthemotor,checktheidenti-

fication marks made during disassembly to make sure

the parts are properly aligned during reassembly.

IMPORTANT: Avoid using excessive clamping

pressureonthemotorhousingtopreventdistorting

the housing.

1.

Lubricate O--rings, pressure seals, back--up gas-

kets, and seal grooves with athin coatofpetroleum jelly.

Lubricate all other internal parts freely with clean hy-

draulic oil.

12.Place motor front flange in a vise and alternately

torque the cap screws from 215 to 280 in--lb (24 to 32

Nm).

2.

3.

the front flange and rear cover. Follow by carefully plac-

ing the back--up rings into the grooves.

Install new shaft seal into front flange.

13.Put a small amount of hydraulic oil in port on motor

and rotate driveshaft one revolution. Protect the shaft if

using a pliers. If drive shaft binds, disassemble motor

and repeat assembly process.

Install lubricated pressure seals into the grooves in

14.Remove

motor from vise.

4.

Install new O--rings to the body.

Hydraulic System (Rev. E)

Page 4 -- 70

Greensmaster 3150

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Greensmaster 3150 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(1 votes, average: 2 out of 2)

Lawn and Garden readers have rated Toro 03113SL Rev E Greensmaster 3150 Service Manual 2.0 out of 2.0 based on 1 product reviews. Safety switches not working