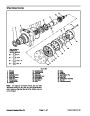

Rotary Cartridge Valves

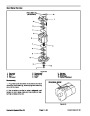

IMPORTANT: Use care when installing the rotary

cartridge valve. Slight bending or distortion of

the stem tube can cause binding and malfunc-

tion. Make sure that deep well socket fully en-

gages the valve base.

1.

Remove rotary handle from valve (Fig. 56):

A. Loosen two (2) set screws that secure handle

cap.

B. Lubricate threads on cartridge valve with clean

hydraulic oil. Thread rotary cartridge valve carefully

into the manifold port. The valve should go in easily

without binding. Torque valve to specification shown

in Figure 55.

B. Remove screw and then lift handle cap from

valve.

C. Locate and retrieve detent pin, compression

spring, bushing and lip seal. The sleeve bearing

should stay in the cap.

6.

Install rotary handle (Fig. 56):

D. Loosen two (2) set screws that secure handle

base to flow control valve and remove base.

A. Placehandlebaseonflowcontrolvalve andposi-

tion alignment mark on base with number 1 on man-

ifold. Secure base with two (2) set screws. Apply a

light coating of grease to chamfer on top of base to

ease seal installation.

IMPORTANT: Use care when removing the rotary

cartridge valve. Slight bending or distortion of the

stemtubecancausebindingandmalfunction.Make

sure that deep well socket fully engages the valve

base.

B. Make sure that sleeve bearing is in handle cap. If

necessary, press sleeve bearing into cap. Install lip

seal on cap with seal lip facing down.

2.

Make sure manifold is clean before removing the

rotary cartridge valve. Remove cartridge valve from

manifold with a deep well socket. Note location of O--

rings and backup rings on valve. Remove and discard

removed seal kit.

C. While pressing on the cap to keep the lip seal in

place, rotate cap in a clockwise direction until the ar-

row on the cap aligns with number 1 on the manifold.

By rotating the cap clockwise, the valve will remain

closed. Install screw to retain cap.

3.

Visuallyinspectthemanifoldportandcartridgevalve

for damage to sealing surfaces, damaged threads, and

contamination.

D. Make sure that alignment marks oncap andbase

areinlineandthatarrowoncapispointingtonumber

1

handle cap.

on manifold. Tighten two (2) set screws to secure

A. Contamination may cause valves to stick or hang

up, it can become lodged in small valve orifices or

seal areas causing valve malfunction.

8

B. If sealing surfaces appear pitted or damaged, the

hydraulic system may be overheating or there may

be water in the system.

2

6

CAUTION

9

10

4

11

Use eye protection such as goggles when using

compressed air.

3

5

7

4.

If necessary, clean cartridge valve using clean min-

1

eral spirits. Submerge valve in clean mineral spirits to

flushoutcontamination.Particlesasfineastalcumpow-

der can affect the operation of high pressure hydraulic

valves. Clean and dry with compressed air.

Figure 56

5.

Reinstall rotary cartridge valve into manifold port:

1.

Handle Base

Handle Cap

7.

8.

9.

Set Screw (2 used)

Screw

2.

3.

4.

5.

6.

A. Lubricate new O-rings and backup rings of seal

kit with clean hydraulic oil and install. The O-rings

and backup rings of seal kit must be arranged prop-

erly on the cartridge valve for proper operation and

sealing.

Detent Pin

Lip Seal

Compression Spring

Bushing

Set Screw (2 used)

10. Sleeve Bearing

11. Flow Control Valve

Hydraulic System (Rev. E)

Page 4 -- 84

Greensmaster 3150

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Greensmaster 3150 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(1 votes, average: 2 out of 2)

Lawn and Garden readers have rated Toro 03113SL Rev E Greensmaster 3150 Service Manual 2.0 out of 2.0 based on 1 product reviews. Safety switches not working