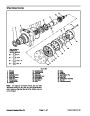

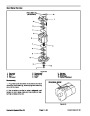

Rear Wheel Motor (Optional 3WD) Removal (Fig. 37)

Before removing any parts from the hydraulic sys-

tem, park the machine on a level surface, engage the

parking brake, lower the cutting units, and stop the en-

gine.

Rear Wheel Motor (Optional 3WD) Installation (Fig.

37)

1.

Note:

Forassemblyofthehubtotherearwheelmotor,

see Rear Wheel (Optional 3WD) Assembly instructions

in Chapter 6 -- Wheels and Brakes.

1.

hydraulic motor and hub assembly (14).

Make sure grease fitting (31) is removed from the

CAUTION

2.

Secure wheel assembly (28) to the four drive studs

of the hydraulic motor and hub assembly with four lug

nuts (30). Torque nuts from 70 to 90 ft--lb (95 to 122

Nm).

Before continuing further, read and become fa-

miliar with General Precautions for Removing

and Installing Hydraulic System Components.

3.

and hub assembly so it points away from the wheel.

Reinstall grease fitting (31) onto hydraulic motor

2.

Chock both front wheels to prevent the machine

from moving. Lift rear wheel off the ground using a jack,

and place blocks beneath the frame. Secure the rear

wheel off the ground.

4.

gette (9) onto the motor shaft.

Slide flangette (11), bearing (10), and relube flan-

3.

Label hoses for reassembly. Remove both hose as-

5.

gettes with bearing, and wheel into the castor fork (6).

Make sure hose fittings on the motor face rearward.

Position hydraulic motor and hub assembly, flan-

semblies (4) and O--rings (23) from the hydraulic fittings

at the hydraulic motor and hub assembly (14). Allow

hoses to drain into a suitable container.

6.

to the inside of the castor fork with both socket head

screws (16), flat washers (18), and lock nuts (29).

Secure hydraulic motor and hub assembly loosely

CAUTION

7.

of the castor fork with cap screws (12), bearing tab (7),

and lock nuts (8).

Secure flangettes with bearing loosely to the inside

Support wheel and motor and hub assembly dur-

ing removal to prevent dropping and causing

personal injury.

A. Position grease fitting on flangette downward.

4.

assembly from the castor fork (6) as follows:

Remove wheel (28) and hydraulic motor and hub

B. Torque socket head screws (16) to 85 ft--lb (115

Nm).

A. Remove cap screws (12) and lock nuts (8) se-

curing flangettes (9 and 11) and bearing tab (8).

C. Torque cap screws (12) to 30 ft--lb (41 Nm).

8.

screws from 80 to 100 in--lb (9.0 to 11.3 Nm).

Apply loctite to both set screws (27). Torque set

B. Remove both socket head screws (16), flat

washers (18), and lock nuts (29).

9.

(23)

hub assembly.

Install both hose assemblies (4) and new O--rings

to the hydraulic fittings at the hydraulic motor and

C. Lower wheel and hydraulic motor and hub as-

sembly from the castor fork.

5.

flangettes and bearing off the motor shaft.

Loosen both set screws (27) on bearing (10). Slide

6.

andhubassembly.Removefourlugnuts(30)andwheel

assembly from the hub drive studs.

Remove grease fitting (31) from the hydraulic motor

Note:

For disassembly of the hub from the rear wheel

motor,seeRearWheel(Optional3WD)Disassembly in-

structions in Chapter 6 -- Wheels and Brakes.

Greensmaster 3150

Page 4 -- 63

Hydraulic System (Rev. E)

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Greensmaster 3150 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(1 votes, average: 2 out of 2)

Lawn and Garden readers have rated Toro 03113SL Rev E Greensmaster 3150 Service Manual 2.0 out of 2.0 based on 1 product reviews. Safety switches not working