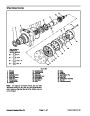

Bedbar Adjuster Service

14

9

6

8

5

13

7

4

2

3

12

11

10

2

1

Figure 14

1.

2.

3.

4.

5.

Adjuster shaft (early production)

Flange bushing

6.

Adjuster screw

Detent

Lock washer

Cap screw

11. Spring

12. Lock nut

13. Adjuster shaft (later production)

14. Retaining ring (later production)

7.

8.

9.

Cutting unit frame

Wave washer

Jam nut (early production)

10. Washer

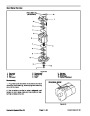

Removal (Fig. 14)

Remove bedbar (see Bedbar Removal in this sec-

2. If flange bushings (2) were removed, align key on

bushing to slot in frame and install bushings.

1.

tion of this manual).

3. Slide adjuster shaft (1 or 13) into flange bushings in

cutting unit frame.

2.

Remove lock nut (12), spring (11), and washer (10)

from adjuster screw.

4. Install wave washer (4) onto adjuster shaft.

5. Secure adjuster shaft to cutting unit frame:

A. On early production cutting units, apply Loctite

3.

4.

Unscrew adjuster screw (6) from adjuster shaft.

Remove adjuster shaft from cutting unit frame:

242

Install jam nut onto adjuster shaft and torque nut

from 15 to 20 ft--lbs (20 to 27 Nm).

(or equivalent) to the threads of the jam nut (5).

A. On early production cutting units, remove jam

nut (5) and wave washer (4) from adjuster shaft (1).

Slide adjuster shaft from frame.

B. On later production cutting units, installretaining

ring(14)toadjustershaft(13).Makesurethatringis

fully seated into shaft groove.

B. On later production cutting units, remove retain-

ing ring (14) and wave washer (4) from adjuster

shaft (13). Slide adjuster shaft from frame.

6.

screw (6) and install into adjuster shaft.

Apply antiseize lubricant to threads of adjuster

5.

unit frame if necessary.

Inspectflangebushings(2)andremovefromcutting

7.

onto adjuster screw.

Install washer (10), spring (11), and lock nut (12)

6.

ting unit frame by removing the cap screw (9) and lock

washer (8).

If the detent (7) is damaged, remove it from the cut-

8. Install bedbar (see Bedbar Installation in this sec-

tion of this manual).

Installation (Fig. 14)

9.

Manual).

Adjust cutting unit (see Cutting Unit Operator’s

1.

cutting unit frame with cap screw and lock washer.

If the detent (7) was removed, secure detent to the

Dual Point Adjust Cutting Units

Page 10 - 12 Rev. E

Greensmaster 3150

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Greensmaster 3150 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(1 votes, average: 2 out of 2)

Lawn and Garden readers have rated Toro 03113SL Rev E Greensmaster 3150 Service Manual 2.0 out of 2.0 based on 1 product reviews. Safety switches not working