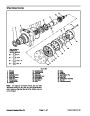

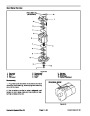

Disassembly (Figs. 68 and 69)

Assembly (Figs. 68 and 69)

IMPORTANT: To prevent damage when clamping

cylinder barrel inavise,clamp only on pivot end.Do

not clamp the vise jaws against the shaft surface.

1. Use a complete repair kit when rebuilding the cylin-

der. Put a coating of clean hydraulic oil on all new seals,

back--up rings, and O--rings.

1.

moving rod in and out of cylinder bore. Plug ports and

clean outside of cylinder.

Pump oil out of cylinder into a drain pan by slowly

2. Install new u--cup, rod wiper, back up ring, and O--

ring ontoeach head.Position O--ring(s),piston ring,and

both wear rings to the piston.

2.

mounting location of cylinder. Do not close vise so firmly

that cylinder barrel could become distorted.

Mount cylinder in a vise by clamping vise on center

3. For serial numbers below 260999999 (Fig. 68), lu-

bricate shaft and piston with clean hydraulic oil.Careful-

ly slide piston onto shaft. Install thread locker on set

screw threads and tighten two (2) set screws to secure

piston to shaft.

3.

Remove the heads from the barrel:

A. For serial numbers below 260999999 (Fig. 68),

loosen set screws and remove threaded cap from

each end of the cylinder barrel.

4.

draulic oil and carefully slide shaft assembly into cylin-

der barrel.

Lubricate shaft and piston assembly with clean hy-

B. For serial numbers above 270000000 (Fig. 69),

use aspanner wrench torotate head clockwise until

the edge of the retaining ring appears in the barrel

opening. Insert a screwdriver under the beveled

edge of the retaining ring to start the retaining ring

through the opening. Rotate the head counter--

clockwise to remove retaining ring from barrel and

head.

5.

and carefully slide them onto shaft and into barrel.

Lubricate head assemblies with clean hydraulic oil

6. Secure heads to barrel:

A. For serial numbers below 260999999 (Fig. 68),

install and tighten threaded caps. Secure both caps

to barrel with set screws.

B. For serial numbers above 270000000 (Fig. 69),

align retaining ring hole in the head with the access

slot in the barrel. Insert the retaining ring hook into

the hole and rotate head clockwise until the retain-

ing ring is completely pulled into the barrel and the

ring ends are covered.

C. Grasp end of rod and use a twisting and pulling

motion to carefully extract rod assembly and head

from cylinder barrel. Remove head from other end

of barrel.

4.

For serial numbers below 260999999 (Fig. 68),

loosen set screws that secure piston to shaft and care-

fully remove piston. Slide head and threaded cap from

shaft. Piston for serial numbers above 270000000 (Fig.

69)

is not removable from shaft.

5.

Remove and discard all seals, back--up rings, and

O--rings from both heads and piston.

CAUTION

Use eye protection such as goggles when using

compressed air to dry cylinder parts.

6.

pressed air. Do not wipe parts dry with paper towels or

cloth. Lint in a hydraulic system will cause damage.

Wash parts in clean solvent. Dry parts with com-

7.

Carefully inspect internal surface of barrel for dam-

age (deep scratches, out--of--round, etc.). Inspect shaft,

both heads, and piston for evidence of excessive scor-

ing, pitting, or wear. Replace entire cylinder if internal

components are found to be worn or damaged.

Greensmaster 3150

Page 4 -- 99

Hydraulic System (Rev. E)

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Greensmaster 3150 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(1 votes, average: 2 out of 2)

Lawn and Garden readers have rated Toro 03113SL Rev E Greensmaster 3150 Service Manual 2.0 out of 2.0 based on 1 product reviews. Safety switches not working