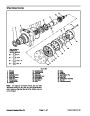

Removal (Fig. 2)

Park machine on a level surface. Make sure engine

5

1.

is off. Set brake and block front wheels.

Jack up and secure the rear wheel off the ground.

The wheel assembly consists of the tire (14),

4

4

2.

3

3

1

1

Note:

rim (15), and valve stem (13) with cap. The hub assem-

bly consists ofthe wheel hub (21), oilseals (18), bearing

cones (19), bearing cups (20), grease fitting (22), and

drive studs (23).

5

2

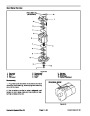

Figure 3

3.

port the rear wheel assembly and pull the castor bolt

from both adapter plates (30 and 33).

Remove lock nut(26) from the castor bolt (34). Sup-

1.

2.

3.

Bearing cup

Wheel hub

Bearing cone

4.

5.

Shaft seal

Drive stud

4.

assemblies from the castor fork (24).

Remove the spacers (16), and the wheel and hub

Disassembly (Fig. 2)

If drive studs (23) are bent or damaged, press studs

1.

5.

remove the castor fork (24) from the frame as follows:

If damage to the castor fork bearings is suspected,

from the wheel hub (21).

2.

cones (19) and bearing cups (20) for damage, and re-

place if necessary.

Remove oil seals (18). Clean and inspect bearing

A. Remove cotter pin (27) and slotted hex nut (28)

securing thesteering cylinder rodend(9)tothecas-

tor fork.

Assembly (Fig. 3)

B. Release the steering cylinder rod end from the

castor fork.

1.

Pack bearing cones (19) with No. 2 multipurpose

lithium base grease and Install bearing cones into the

wheel hub.

C. Removethefourhexheadscrewsandflatwash-

ers securing the fuel tank to the frame.

2.

Grease inner edge of the new shaft seals (18) with

D. Tiltrearoffueltankuptogainaccesstothetopof

the castor fork. Support fuel tank securely.

No. 2 multipurpose lithium base grease. Install new

shaft seals (18) into the hub with the lip of the seals fac-

ing towards the inside.

CAUTION

3.

hub (21).

If removed. press new drive stud (23) into the wheel

Support the castor fork while removing the

slotted hex nut (5) to prevent the fork from drop-

ping and causing personal injury.

Installation (Fig. 2)

1.

Slide wheel assembly onto the drive studs (23).

Tighten lug nuts (11) to the drive studs evenly in a cris--

cross pattern to a torque of 70 to 90 ft--lb (95 to

E. Remove cotter pin (6) and slotted hex nut (5)

fromthecastorforkshaft.Lowercastorforkfromthe

frame.

122

Nm).

2.

If the bearings in the castor fork pivot housing were

removed, install castor fork (24) to the frame as follows:

F. Cleanandinspectbearingcones(3)andbearing

cups (2) for damage, and replace if necessary.

A. Press new bearing cups (2) into the castor fork

pivot housing with the thick side of the cups facing

towards the inside.

6.

Removelugnuts(11)fromthedrivestuds(23)ofthe

wheel hub assembly (17). Separate wheel and hub as-

semblies.

B. Pack bearing cones (3) with No. 2 multipurpose

lithium base grease.

C. Coat castor fork shaft with antiseize lubricant

and place two steering washers (4) onto the castor

fork shaft. Slide lower bearing cone onto castor fork

shaft with the wide edge of the bearing against the

washers.

Wheels and Brakes

Page 6 -- 4

Greensmaster 3150

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Greensmaster 3150 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(1 votes, average: 2 out of 2)

Lawn and Garden readers have rated Toro 03113SL Rev E Greensmaster 3150 Service Manual 2.0 out of 2.0 based on 1 product reviews. Safety switches not working