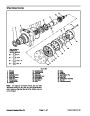

Removal (Fig. 70)

Before removing any parts from the hydraulic sys-

1.

tem, park machine on a level surface, set brake, lower

cutting units, and stop engine.

PUMP INLET HOSE

CAUTION

Before continuing further, read and become fa-

miliar with General Precautions for Removing

and Installing Hydraulic System Components.

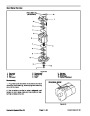

Figure 71

2.

Place a clean container, large enough to collect 2

gallons(7.6liters),underthehydrostattocollecthydrau-

lic oil.

Assembly (Fig. 70)

1.

2.

auxiliarytank.Torquegaugefrom100to125in--lb(11.3

to 14.1 Nm).

Coat all O--rings with clean hydraulic oil.

Secure sight gauge (11) and new O--ring (12) to the

3.

Clamppumpinlethosetocontroldrainage.Remove

pump inlet hose from hydrostat. Release clamp from

hose and drain about 2 gallons (7.6 liters) from the hy-

draulic tank (Fig. 71).

4.

al hydraulic oil.

Clamppumpinlethose toprevent draining addition-

3.

(15)

Secure hydraulic barb fittings (28) and new O--ring

to the auxiliary tank. Torque fitting from 17 to 21 ft--

lb (23 to 28 Nm).

5.

Remove cap screw (31) and flat washer(30) secur-

ing the tether (29) to the auxiliary tank.

4.

Secure valve hose (32) to the barb fitting (28) with

hose clamp (13).

6.

Unplug leak detector harness from the main tractor

harness.

5.

(15)

Secure bothhydraulic barbfittings (14)andO--rings

to the valve body (22)

7.

Remove four cap screws (6 and 9), flat washers (4),

neoprene washers (3), and spacers (3 and 10).

Installation (Fig. 70)

8.

flow hose (27).

Looseneitherhoseclamp(26)anddisconnectover-

1.

if previously removed.

Connect tank hose (23) and install valve assembly

9.

and disconnect valve hose (32) at valve fitting. Remove

auxiliary tank assembly.

Lift auxiliary tank slightly, loosen hose clamp (13),

2.

Connect pump inlet hose to hydrostat (Fig. 71).

3. Connect overflow hose (27).

10.

(13)

ting(14).Removetwocapscrews(25)andlockwashers

If valve removal is necessary, loosen hose clamp

and disconnect tank hose (23) at hydraulic tank fit-

4. Position auxiliary tank over hydraulic tank and con-

nect valve hose (32).

(24)

and remove the valve assembly.

securing the valve assembly to the hydraulic tank

IMPORTANT: Do not over tighten cap screw.

Threads in tank may become damaged.

Disassembly and Inspection (Fig. 70)

5. Install four spacers (3 and 10), neoprene washers

(3),

flat washers (4), and cap screws 6 and 9). Tighten

1.

leak detector assembly drawing (Fig. 70) as a guide.

The leak detector can be disassembled using the

cap screws from 30 to 60 in--lb (3.4 to 6.8 Nm).

6.

Connect leak detector harness to main wire har-

2.

Inspect parts for the following:

ness.

A. Leaking, cracked, or damaged auxiliary tank.

7. Secure tether to the auxiliary tank with cap screw

(31)

and flat washer (30).

B. Wornor leaking hydraulic hoses.Replace ifnec-

essary.

Note:

Monitor hydraulic fluidlevelinsightglass.Asair

is removed from the hydraulic circuit, auxiliary tank may

need to be topped off after initial fill.

C. Visibly worn or damaged parts.

Greensmaster 3150

Page 4 -- 101

Hydraulic System (Rev. E)

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Greensmaster 3150 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(1 votes, average: 2 out of 2)

Lawn and Garden readers have rated Toro 03113SL Rev E Greensmaster 3150 Service Manual 2.0 out of 2.0 based on 1 product reviews. Safety switches not working