Disassembly (Fig. 5)

Remove grease seal (9) and snap ring (18) from the

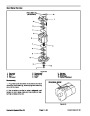

OUTER BEARING EDGE

MUST BE FLUSH WITH EDGE

1.

long end of hub (2).

2.

Remove washer (7), two thrust washers (6), and

hub (2) from the hydraulic motor shaft. Remove remain-

ingtwothrustwashers(6),washer(7),snapring(8),and

grease seal (9) from the shaft.

3.

If drive studs (4) are bent or damaged, press studs

from the wheel hub (2).

ARROWS ON BEARING

TOWARDS LONG END

4.

Press clutch roller bearings (3) from the hub (2).

Assembly (Fig. 5)

If drive studs (4) were removed, press new studs

Figure 6

1.

into the wheel hub (2).

Installation (Fig. 4)

1.

Secure wheel (28) to the four drive studs of the hy-

draulic motor and hub assembly (14) with four lug nuts

Torque nuts from 70 to 90 ft--lb (95 to 122 Nm).

2.

follows (Fig. 6):

Press roller clutch bearings (3) into the hub (2) as

(30).

Note:

Arrow on the side of the clutch roller bearings

2.

hub assembly (14) so it points away from the wheel.

Reinstall grease fitting (31) into hydraulic motor and

(3)

must point to the long side of the end of the hub (2).

A. Press two bearings into each end of the hub.

3.

Install flangette (11), bearing (10), and relube flan-

gette (9) onto the motor shaft.

B. The outer edge of the outer bearings must be

flush with the recessed edge within the hub.

4.

Position hydraulic motor and hub assembly (14),

flangettes (9 and 11) with bearing (10), and wheel (28)

into the castor fork.Make sure hose fittings on the motor

face to the rear.

C. Center bearings must not interfere with grease

fitting hole.

3.

Grease inner edge of the new grease seals (9) with

5.

loosely totheleftinside ofthe castor fork with both sock-

et head screws (16) lock nuts (13).

Secure hydraulic motor and hub assembly (14)

No. 2 multipurpose lithium base grease. Slide one seal

onto motor shaft past groove closest to the motor.Install

snap ring (8) into groove.

6.

Secure flangettes (9 and 11), and bearing (10)

4.

the motor shaft. Slide hub (2) onto the shaft with the

short side first.

Slideflatwasher (7)andtwothrustwashers (6)onto

loosely to the right inside of the castor fork with cap

screws (12), bearing tab (7), lock nuts (8 and 29), and

flat washer (18).

5.

(7)

into the shaft groove. Slide remaining new grease seal

(9) onto motor shaft.

Slide remaining thrust washers (6) and flat washer

onto the motor shaft. Install remaining snap ring (8)

A. Position flangette grease fitting facing down-

ward.

B. Torque socket head screws (16) to 85 ft--lb

(115

Nm).

IMPORTANT:The hub (2) should spin freely in the

forward direction, but lock on the hydraulic motor

shaft when it is spun in the reverse direction.

C. Torque cap screws (12) to 30 ft--lb (41 Nm).

7.

screws from 80 to 100 in--lb (9 to 11 Nm).

Apply loctite to both set screws (27). Torque set

6.

flush with the end of the hub.

Press grease seals (9) into the hub (2) so they are

Wheels and Brakes

Page 6 -- 8

Greensmaster 3150

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Greensmaster 3150 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(1 votes, average: 2 out of 2)

Lawn and Garden readers have rated Toro 03113SL Rev E Greensmaster 3150 Service Manual 2.0 out of 2.0 based on 1 product reviews. Safety switches not working