9.

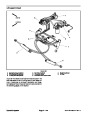

Disconnect throttle cable from the speed control le-

ver by removing the flat washer and lock nut (Fig. 14).

Loosen jam nut and separate cable from cable support.

Position cable away from engine.

1

10.Remove

fasteners that secure the upper radiator

shroud to the lower shroud and radiator (see Radiator

Removal in this section). Position coolant reservoir and

bracket away from the radiator. Remove upper radiator

shroud from machine.

3

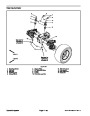

11.

(Fig. 15).

Remove fan hub and fan from hydraulic fan motor

2

A. Remove hex nut(item 9) and washer (item 8)that

secure fan hub and fan assembly to fan motor.

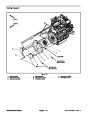

Figure 13

NOTE: The fan motor shaft is tapered.

1.

2.

Fuel pump

Fuel supply hose

3.

Throttle cable

B. Usesuitable pullertoremove fanhub(withfanat-

tached) from fan motor shaft taking care to not dam-

age fan. Remove fan hub and fan from machine.

1

2

3

4

5

IMPORTANT: The hydraulic pump assembly can re-

main in machine during engine removal. To prevent

pump from shifting or falling, make sure to support

pump assembly before mounting fasteners are re-

moved.

8

6

12.Support

hydraulic pump assembly. Remove fasten-

7

ers that secure pump assembly to engine (see Pump

Assembly Removal in the Service and Repairs section

of Chapter 4 -- Hydraulic System).

12

9

10

13.Make

fuel lines or hydraulic hoses to the engine are removed.

sure all cable ties securing the wiring harness,

11

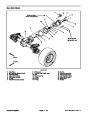

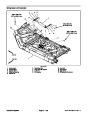

Figure 14

14.Connect

15.Remove

screws securing the engine mounts to the engine sup-

ports.

hoist or lift to the lift tabs on engine.

1.

2.

3.

4.

5.

6.

Lock nut

7.

8.

9.

10. Cap screw (2 used)

11. Throttle cable

12. Cable support

Flange head screw

Spring washer (2 used)

Ball joint

Flat washer

Throttle lever

Lock nut

flange nuts, rebound washers and cap

Flange head screw

Cap screw

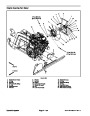

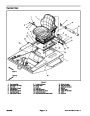

Engine Installation (Fig. 9)

Ifremoved,installengine mounts totheengineusing

CAUTION

1.

Figure 9 as a guide.

One person should operate lift or hoist while

another person guides the engine out of the ma-

chine.

2.

Connect hoist or lift to the engine lift tabs.

IMPORTANT: Make sure not to damage the engine,

fuel and hydraulic lines, electrical harness or other

components while removing the engine.

CAUTION

One person should operate lift or hoist while

another person guides the engine into the ma-

chine.

16.Slowly

remove engine assembly from the machine.

17.If

necessary,remove engine mounts fromtheengine

using Figure 9 as a guide.

IMPORTANT: Make sure not to damage the engine,

fuel and hydraulic lines, electrical harness or other

parts while installing the engine.

Kubota Diesel Engine

Page 3 -- 14

Groundsmaster 4100--D

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 30413, Toro Groundsmaster Groundsmaster 4100 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)

At only 700mm wide the Mini Dumper is even at home on tight access

sites. No need to grunt, groan, and force the

mower about the yard. The US will be getting a revised 2011 Jeep Wrangler but the diesel option will not be offered in the United States.