3.

4.

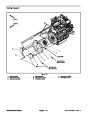

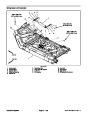

pumpinputshaft.Secureenginetoenginesupportswith

cap screws, rebound washers and flange nuts.

Slowly lower engine into the machine.

27

(37 to 44 N--m)

to 33 ft--lb

Align engine to the engine supports and hydraulic

1

10

11

5.

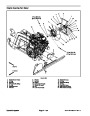

Pump Assembly Installation in the Service and Repairs

section of Chapter 4 -- Hydraulic System).

Secure hydraulic pump assembly to engine (see

2

9

8

3

6.

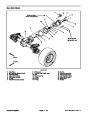

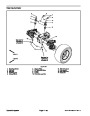

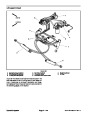

Thoroughly clean tapered surfaces of fan motor

shaft and fan hub. Position fan hub (with fan attached)

onto motor shaft and secure with washer and hex nut

(Fig. 15). Torque nut from 27 to 33 ft--lb (37 to 44 N--m).

5

4

6

7

12

to 14 ft--lb

to 18 N--m)

7.

Position upper radiator shroud and coolant reservoir

(17

withbrackettotheradiator.Secureshroudandreservoir

bracket to the radiator and lower radiator bracket with

removed fasteners (seeRadiator Installation in thissec-

tion). Make sure thatclearance between shroud and fan

is at least 0.180” (4.6 mm) at all points.

Figure 15

1.

Fan motor

7.

8.

9.

Cap screw (4 used)

Hex nut

2.

3.

4.

5.

6.

Cap screw (2 used)

Flat washer (2 used)

Fan motor bracket

Lock nut (2 used)

Washer (4 used)

Washer

10. Fan hub

11. Fan

8.

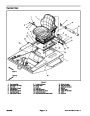

Connect throttle cable to the speed control lever with

washer and lock nut (Fig. 14). Secure cable to cable

support. Adjust throttle cable.

13.Connect

diator drain is shut. Fill radiator and reservoir with cool-

ant.

coolant hoses to the radiator.Make sure ra-

9.

Connect fuel line to the injection pump.

wires and/or electrical connections to the

10.Connect

14.Check position of wires, fuel lines, hydraulic hoses

and cables for proper clearance with rotating, high tem-

perature and moving components.

following electrical components:

A. The dual temperature switch, temperature send-

er and alternator (Fig 10).

15.Position battery to machine. Connect positive bat-

tery cable first and then negative battery cable. Secure

battery to machine with strap and cover.

B. The engine run solenoid and fuel pump (Fig. 13).

C. The glow plug (Fig. 11).

16.Check and adjust engine oil as needed.

17.Check and adjust hydraulic oil as needed.

D. Battery,frameandwireharnessgroundtotheen-

gine block.

18.Bleed

fuel system.

E. The starter and low oil pressure switch (near

starter).

19.Start engine and operate hydraulic controls to prop-

erly fill hydraulic system (see Charge Hydraulic System

in Chapter 4 -- Hydraulic System).

11.

Installaircleanerassembly totheengine(seeAirFil-

ter System Installation in this section).

20.Close

and secure hood.

12.Install

exhaustsystemtomachine(seeExhaustSys-

tem Installation in this section).

Groundsmaster 4100--D

Page 3 -- 15

Kubota Diesel Engine

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 30413, Toro Groundsmaster Groundsmaster 4100 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)

At only 700mm wide the Mini Dumper is even at home on tight access

sites. No need to grunt, groan, and force the

mower about the yard. The US will be getting a revised 2011 Jeep Wrangler but the diesel option will not be offered in the United States.