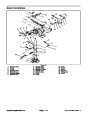

Disassembly

CAUTION

1.

Plug all ports and clean the outside of the valve thor-

oughly.

Use eye protection such as goggles when using

compressed air.

IMPORTANT: Match--mark spools to their associat-

ed bores before disassembly. Spools must be rein-

stalled to the bore from which they were removed.

1.

Clean all metal parts with solvent and blow dry with

compressed air.

2.

blies from their bores.

Remove both spool caps and slide the spool assem-

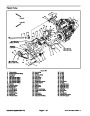

2.

washers with new ones.

Replace check poppets, o--rings, and back--up

3.

sembly.

Remove o--ring and bushing from each spool as-

3.

4.

5.

Install new o--rings into the valve body.

Slide bushings and new o--rings over the spools.

If a spool was disassembled, install washer, spool

4.

ends that are opposite the spool caps.

Removewipersealsando--ringsfromthespoolbore

spring, spacer, and retaining ring to the spool.

Note:

Disassemble spool assemblies only if the re-

taining ring, spacer, spring, or washer need replacing.

6.

Lubricate spools liberally with clean hydraulic fluid

and install into their proper bore.

5.

Remove seat retaining plugs, back--up washers, o--

rings, and check springs from the valve body.

7.

20

Install spool caps into valve body. Torque caps from

to 25 ft--lb (27 to 34 N--m).

6.

Remove check poppets, seats, o--rings, and plung-

ers from the valve body.

8.

Lubricate both plungers liberally with cleanhydraulic

fluid and install into their proper bore.

7.

Remove solid plug, back--up washer, and o--ring

from the opposite end of the plunger.

9.

Installnewo--rings,seats,checkpoppets,andcheck

springs into the plunger bores.

8.

Remove plug and o--ring from the top of the valve

body next to the detent plug.

10.Install

o--rings, back--up washers, and seat retaining

plugsintotheirplungerbores.Torquebothplugsfrom30

to 35 ft--lb (41 to 48 N--m).

9.

Remove disc, spring, and detent plunger from the body.

Remove detent plug and o--ring from the valve body.

11.

into the bore with the grooved plunger. Torque plug from

30 to 35 ft--lb (41 to 48 N--m).

Install new o--ring, back--up washer, and solid plug

Inspection

1.

Inspect spools and spool bores for wear. If wear is

excessive, replace valve with new one.

12.Install

new o--ring, seat, check poppet, check spring,

2.

3.

Inspect springs and replace as necessary.

new o--ring, back--up washer, and seat retaining plug

into the bore with the plunger. Torque plug from 30 to 35

ft--lb (41 to 48 N--m).

Inspect plunger, detent plunger, and check poppet

for wear. Replace as necessary.

13.Install

next to the detent plug bore. Torque plug from 10 to 12

ft--lb (14 to 16 N--m).

o--ring and plug into the top of the valve body

4.

as necessary.

Inspect seat, spacer, and bushing for wear. Replace

5.

6.

Inspect disc and washer. Replace as necessary.

Inspect cap and plugs for damaged threads and in-

14.Lubricate

with clean hydraulic fluid and install into its valve body

bore.

plunger detent, spring, and disc liberally

spect o--ring sealing surfaces. Replace as necessary.

15.Install

Torque plug from 30 to 42 ft--lb (41 to 57 N--m).

o--ring and detent plug into its proper bore.

Assembly

IMPORTANT: Do not wipe parts with dry paper tow-

els or rags. Lint may cause damage to the hydraulic

system.

Hydraulic System (Rev. D)

Page 4 -- 92

Groundsmaster 3500--D

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3500 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)