5.

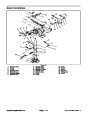

Inspect wear plates for the following:

8. Install rear wear plate with pressure seal side up and

open side of the pressure seal pointing to the suction

side of the pump.

A. Bearingareasshouldnothaveexcessive wearor

scoring.

9.

and o--ring grooves in the front body. Install new o--rings

to the front body.

Applyalightcoatingofpetroleumjellytonewo--rings

B. Face of wear plates that are in contact with gears

should be free of wear, roughness or scoring.

C. Thickness of wear plates should be equal.

10.Install

locatingdowelsinfrontbody.Alignmarkerline

on the body and front plate.

6.

Inspect front plate, back plate, and adapter plate for

damage or wear.

IMPORTANT: Do not dislodge pressure seals,

back--upgasketsoro--ringsduringpumpassembly.

Assembly (Fig. 71)

11.

hand pressure should be sufficient to engage the dow-

els.

Gently slide the front body onto the assembly. Firm

Note:

line on each part to make sure the parts are properly

aligned during reassembly.

When assembling the pump, check the marker

12.Check

tomakesurethatthesurfaceofthewearplate

1.

and wear plates with a thin coat of petroleum jelly. Lubri-

cateallotherinternalpartsfreelywithcleanhydraulicoil.

Lubricate o--rings,pressureseals,back--upgaskets,

is slightly below the face of the front body. If the wear

plate is not below the front body, check assembly for a

shifted pressure seal or o--ring.Correct before proceed-

ing.

NOTE: A seal and retaining ring are not necessary in

the front plate. The gear pump seal kit does not include

these parts.

13.Apply

alightcoatingofpetroleumjellytotheexposed

side of the adapter plate.

2.

machined surface facing up.

Place front plate on a flat surface with the internal

14.Place

for proper location. Firm hand pressure should be suffi-

cient to engage the dowels.

adapter plate on assembly using marker line

3.

Apply a light coating of petroleum jelly to the pres-

sure seals, back--up gaskets, and wear plate grooves.

15.Install

coupler into drive gear.

4.

Install the pressure seals, flat side outward, into the

16.Follow

pump using the same precautions, lubrication, and

alignment.

above procedure to install back section of the

grooves in the wear plates. Follow by carefully placing

the backup gaskets, flat side outward, between the

pressure seals and the groove in the wear plate.

17.Install

the four screws and hand tighten.

5.

Applyalightcoatingofpetroleumjellytotheexposed

side of the front plate.

18.Place

mounting flange of the pump into a vise with

soft jaws. Alternately torque the screws from 38 to 43 ft--

lb (51 to 58 N--m).

6.

Lubricatethedrivegearshaftwithcleanhydraulicoil.

Insert the drive end of the drive shaft through the wear

platewiththepressuresealsidedownandtheopenside

of the pressure seal pointing to the suction side of the

pump. Carefully install shaft into front plate.

19.Remove

pump from vise.

20.Place asmallamountofcleanhydraulicoilintheinlet

ofthepumpandrotatethedriveshaftawayfromtheinlet

one revolution. If any binding is noted, disassemble the

pump and check for assembly problems.

7.

Lubricate thefront idlergear shaftwith clean hydrau-

lic oil. Install idler gear shaft into the remaining position

in the wear plate. Apply a light coating of clean hydraulic

oil to gear faces.

Hydraulic System (Rev. D)

Page 4 -- 104 Rev. F

Groundsmaster 3500--D

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3500 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)