Procedure for Deck Motor Efficiency -- Case Drain

Test:

11.Stop cutting units by positioning the PTO switch to

the DISENGAGE position. Stop engine.

1.

perature by operating the machine for approximately 10

minutes. Make sure the hydraulic tank is full.

Make sure hydraulic oil is at normal operating tem-

12.Identify amount of oil collected in the container. Re-

cord test results.

13.If

flow was greater than 22.4 ounces (662 millili-

2.

Removebladesfromallcuttingdecks.Lowerthecut-

ters), repair or replace the tested deck motor.

ting units.

14.Relieve

hydraulic system pressure (See Relieving

3.

units raised and off. Make sure engine is off and the

parking brake is engaged.

Park the machine on a level surface with the cutting

Hydraulic System Pressure in the General Information

section). Disconnect tester from motor and hose. Re-

connect hydraulic hoses.

4.

Read Precautions for Hydraulic Testing.

The deck motors are connected in series. To

15.Repeat test with other deck motors as needed.

Note:

16.Install cutting blades after testing is completed (see

Cutting Unit Operator’s Manual).

isolate a faulty motor, you may have to test all three mo-

tors in the circuit by starting with the upstream motor

first.

4

5.

Forthesuspectedbaddeckmotor,disconnectreturn

hose fromthemotor.Note: the return hose is on the mo-

tor side that includes the relief valve (Fig. 32).

3

6.

with the motor and the disconnected return hose. Make

sure the tester flow control valve is fully open.

Install hydraulic tester (pressure and flow) in series

2

7.

Disconnect hose from deck motor case drain at the

bulkhead T--fitting (Fig. 33). Plug the T--fitting. Place

open end of disconnected case drain hose into a drain

pan.

1

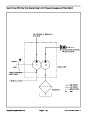

Figure 32

1.

2.

Deck motor

Return line

3.

4.

Relief valve

Case drain hose

8.

One person should sit on the seat and operate the

machine while another person reads the tester and

measures deck motor case drain leakage. Make sure

traction pedal is in NEUTRAL. Start engine and move

the throttle to full speed (3050 + 50 RPM).

3

2

CAUTION

6

5

1

Keepawayfromdecksduringtesttopreventper-

sonal injury from rotating parts.

RIGHT

1

9.

Engage decks by positioning the PTO switch to the

FRONT

ENGAGE position. While watching hydraulic tester

pressure gauge, slowly close flow control valve until a

pressure of 1200 PSI is obtained.

4

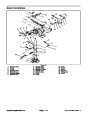

Figure 33

10.After

achieving 1200 PSI, place disconnected motor

1.

2.

3.

Deck motor

Rear case drain hose

Rear T--fitting

4.

5.

6.

Front LH case drain

Front RH case drain

Front T--fitting

case drain hose into a container graduated in ounces or

milliliters (e.g. Toro #TOR4077) and collect hydraulic

fluidfor15seconds.After15seconds,remove hoseend

from container.

Groundsmaster 3500--D

Page 4 -- 49

Hydraulic System (Rev. D)

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3500 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)