Assembly

IMPORTANT: When greasing spindles, grease

passes into the center of the shaft and out to fill the

bearing cavity of the housing. If grease does not

come out of lower seal when greasing, check lu-

brication hole in spindle shaft for obstruction.

IMPORTANT: If new bearings will be installed into a

used spindle housing that has the original large

snap ring installed, discard the snap ring that came

with the new bearings because it is not necessary

to replace the original snap ring. However, new

bearings with their matched spacer set and snap

ring must always be installed when the spindle

housing is being replaced. Replacement bearings

are sold only with a matched snap ring and spacer

set. These parts cannot be purchased separately.

10.Install spindle plug to top of spindle housing. Attach

a hand pump grease gun to either grease fitting and fill

housing cavity with grease until grease starts to come

out of lower seal. NOTE: Pneumatic grease guns can

produce air pockets when filling large cavities.

11.

Install spindle housing and spindle plate to deck with

1.

spindle housing, install snap ring into spindle housing

groove. Make sure snap ring is seated in groove.

If large snap ring was removed, or if replacing the

cap screws and flange nuts. Notches on housing and

plate should be aligned to front of deck.

12.Install

cutting blade, anti--scalp cup and bolt (see

IMPORTANT: If bearings are being replaced, make

sure to use the large spacer, inside spacer, and

spacer ring that are included in new bearing set.

Cutting Blade Removal and Installation). Tighten blade

bolt from 85 to 110 ft--lb (115 to 149 N--m).

13.Position

O--ring to top of spindle housing. Install hy-

2.

spindlehousing.Thespacershouldfittightly againstthe

snap ring.

Using an arbor press, push large spacer into top of

draulic motor to the cutting unit with two cap screws.

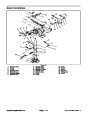

PRESS

3.

Thoroughly oil the bearing cups. Using an arbor

4

press, push the bearing cups into the top and bottom of

the spindle housing. The top bearing cup must contact

the spacer previously installed, and the bottom bearing

cup must contact the snap ring. Make sure that the as-

sembly is correct by supporting the first bearing cup and

pressing the second against it (Fig 28).

3

1

2

6

4.

Pack the bearing cones with grease. Apply a film of

5

grease on lips of seals.

5.

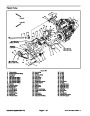

housing. Note: The bottom seal must have the lip facing

out (down) (Fig. 29).

Install lower bearing and seal into bottom of spindle

Figure 28

4.

5.

6.

1.

2.

3.

Bearing cups

Large snap ring

Large spacer

Arbor press

Support

Arbor press base

6.

Slide spacer ring and inside spacer into spindle

housing, then install upper bearing and seal into top of

housing. Note: The upper seal must have the lip facing

out (up) (Fig. 29).

2

7.

Inspect the spindle shaft to make sure it is free of

burrs or nicks that could possibly damage the seals.

Also, make sure that lubrication hole in shaft is clean.

Lubricate the shaft with grease.

8.

Install spindle spacer onto shaft. Carefully slide

spindle shaft through spindle housing. The bottom seal

and spindle spacer fit together when the spindle is

installed fully.

9.

131

Thread spindle nut onto shaft and tighten nut from

to 159 ft--lb (178 to 216 N--m).

1

Figure 29

1.

Bottom seal installation

2. Upper seal installation

Groundsmaster 3500--D

Page 7 -- 19 Rev. E

Cutting Units (Rev. D)

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3500 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)