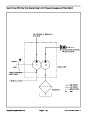

Procedure for Piston Pump (P3) Flow and Traction

Relief Pressure Test:

13.Verify traction relief valve setting byclosing flowcon-

trol valve on tester. System pressure should be 3500

PSI as the relief valve lifts. If pressure can not be met or

is exceeded with traction pedal fully depressed, release

traction pedal and open flow control valve fully.

1.

Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately 10

minutes.

14.If

specification is not met consider the following:

2.

Parkmachineonalevelsurfacewiththecuttingunits

lowered and off. Make sure engine is off.

A. The traction belt may be worn and slipping (see

Replace Traction Belt).

3.

4.

Read Precautions for Hydraulic Testing.

B. The relief valve leaks or is faulty and needs re-

placement.

Make sure that traction pedal is adjusted to the neu-

tral position (see Adjust Traction Drive for Neutral in the

Adjustments Section).

C. The hydrostat needs to be repaired or replaced

as necessary.

CAUTION

15.If the traction relief valve tests out properly, verify

pump flow as follows:

A. Apply traction pedal until pressure gauge reads

1000 PSI. Verify with a phototac that the pump

speed is 2350 RPM (engine speed approximately

2450 RPM).

One front wheel and the rear wheel will be off the

ground during testing. Make sure machine is

supported so it will not move and accidentally

fall to prevent injuring anyone under machine.

B. Observe flow gauge. TESTER READING should

be approximately 12.5 GPM.

5.

Block up one front traction wheel and the rear wheel

off the floor to allow flow through the traction circuit; dis-

connect brake linkage to the raised front wheel (see

Wheels and Brakes -- Chapter 7).

16.Release

traction pedal and turn off machine.

Note:

If pressure is good under no load, but drops be-

6.

of the machine.

Chock remaining front wheel to prevent movement

low specification when under traction load, the piston

pump and/or wheel motor(s) should be suspected of

wear. When a pump and/or motor is worn or damaged,

thechargepumpisnotabletokeepupwithinternalleak-

age in the traction circuit (See Test #3).

7.

and something immovable in the shop.

Attachaheavychaintotherearofthemachineframe

8.

9.

Make sure parking brake is on.

17.If

be repaired or replaced as necessary.

specifications are not met, the hydrostat needs to

Disconnect hose from the lower hydraulic fitting on

the engine side of the hydrostat (Fig. 18).

18.Disconnect

tester from hydraulic fitting and hose.

10.Install

tester in series with the pump and the discon-

Reconnect hose to pump connection.

nected hose. Make sure the tester flow control valve is

fully open.

19.Reconnect

Brakes -- Chapter 7).

brake linkage to wheel (see Wheels and

11.

50

Start engine and move throttle to full speed (3050 +

RPM).

CAUTION

2

Use extreme caution when taking gauge read-

ings. The front tire on the ground will be trying to

move the machine forward.

1

12.Slowly

push traction pedal fully to forward position.

Figure 18

1.

Lower hydraulic fitting

2.

Piston pump

Groundsmaster 3500--D

Page 4 -- 33

Hydraulic System (Rev. D)

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3500 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)