3.

From the roller tube end with only the inner seal

NOTE: After roller is installed to cutting deck, lubricate

roller grease fittings, rotate roller to properly distribute

grease in bearings and clean excess grease from roller

ends. A properly assembled roller should rotate with

less than 5 in--lbs (0.68 N--m) resistance.

installed, carefully install the roller shaft into the roller

tube. Make sure that seals are not damaged as shaft is

installed.

4.

Install new bearing and outer seals into second end

of roller tube:

1

3

4

2

5

A. Position a second new bearing to roller shaft and

tube.Position washer(seeSpecialTools)onbearing

to allow pressing on both inner and outer bearing

races simultaneously.

B. Use washer and bearing/outer seal tool (see

Special Tools) with a soft face hammer to fully seat

bearing (Fig. 23). After bearing installation, make

sure that shaft freely rotates and that no binding is

detected. If necessary, lightly tap bearing and/or

shaft ends to align shaft and bearings. Remove

washer from roller.

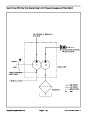

Figure 22

4.

5.

1.

2.

3.

Roller tube

Inner seal

Bearing

Outer seal

Bearing/outer seal tool

C. Apply a small amount of grease around the lip of

both outer seals.

1

2

3

4

5

D. Carefully install first outer seal into roller tube

making sure that seal lip (and garter spring) faces

end of tube. Use bearing/outer seal tool (see Special

Tools) and soft face hammer to lightly seat seal (Fig.

6

24).

Make sure that shaft and bearings still freely ro-

tate after seal installation.

E. Using the same process, install second outer

sealmakingsuretonotcrushtheinstalledouterseal.

Again, make sure that shaft and bearings still freely

rotate.

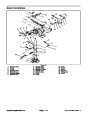

Figure 23

IMPORTANT: Make sure that all grease is removed

from shaft threads to prevent bearing lock nut loos-

ening.

1.

2.

3.

Roller tube

Roller shaft

Inner seal

4.

5.

6.

Bearing

Washer

Bearing/outer seal tool

5.

shaft.

Thoroughly clean threads on both ends of roller

1

2

3

4

5

6

NOTE: If original bearing lock nut(s) are being used,

apply Loctite #242 (or equivalent) to threads of lock

nut(s).

6.

shaft. Make sure that outer seals are not damaged dur-

ing nut installation. Torque lock nuts from 50 to 60 ft--lb

Install bearing lock nut onto each end of the roller

(68

to 81 N--m).

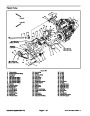

Figure 24

4.

5.

6.

7.

If set screw was removed from either end of roller

1.

2.

3.

Roller tube

Roller shaft

Inner seal

Bearing

Outer seal

Bearing/outer seal tool

shaft, apply Loctite #242 (or equivalent) tothreads ofre-

moved set screw and install into roller shaft. Tighten set

screw until it bottoms in shaft and is recessed in shaft.

IMPORTANT: When roller assembly is installed to

cutting deck, make sure that grease groove in each

roller mount aligns with the grease hole in each end

of roller shaft.

Groundsmaster 3500--D

Page 7 -- 15 Rev. E

Cutting Units (Rev. D)

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 3500 D |

| Download File |

|

| Document Type | Catalog |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)