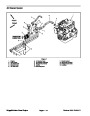

Disassembly (Fig. 5 and 6)

Partially loosen wheel nuts then jack up and support

B. Replace drums if they are cracked or heat

spotted.

1.

vehicle (see Jacking Instructions in Operator’s Manual).

Remove wheel nuts and then remove wheel.

C. Scoring, grooves, taper, out of round and glazing

can be machined out as long as the oversize limit is

not exceeded. Minor scoring or glazing can be re-

moved with sand paper.

2.

If servicing rear brakes, loosen set screw on parking

brake control lever knob. Turn knob on parking brake le-

ver counterclockwise all the way to loosen parking brake

cable adjustment.

IMPORTANT: If one drum is machined, the drum on

the opposite side should be machined to the same

diameter to maintain equal braking forces.

NOTE: It may be necessary to back off adjuster to re-

move brake drum. To back off adjuster, rotate brake

drum until access hole lines up with bolt adjuster on ad-

juster assembly. Use a hooked piece of wire to pull pawl

away from bolt adjuster, then turn bolt adjuster.

D. Wipe braking surface of drum after machining

with a cloth soaked in denatured alcohol.

2.

Inspect brake shoe and lining set (13).

IMPORTANT: Shoe and lining sets should be re-

placed for both wheels on the axle. Equal braking

forces must be maintained.

3.

Remove brake drum.

4.

If servicing front brakes, remove wheel hub from ve-

hicle (see Front Wheel Assembly (2 Wheel Drive) in this

section for series 3000 Workman vehicle or see Front

Wheel and Axle Housing Assembly in the Service and

Repairs section of Chapter 10 – Front Wheel Drive

A. Replace if linings are excessively worn or dam-

aged. Oil, grease or brake fluid contamination is not

acceptable.

(4WD)

for series 4000 Workman vehicle).

B. Replace if shoe webbing show signs of overheat-

ing as indicated by a slight blue color.

5.

If servicing rear brakes, remove stub axle from ve-

hicle (see Stub Axle and Drive Shaft Service in the Ser-

vice and Repairs section of Chapter 6 – Drive Train).

3.

(23)

Inspect hold down washer (22), hold down spring

and hold down pin (26). Replace parts if rusted, cor-

roded or bent. Replace washers and springs if they are

unable to lock onto the pin.

6.

and then lower shoe spring (15).

Remove upper shoe spring (14), adjuster spring (20)

NOTE: The adjuster assembly (27) consists of the fe-

male push rod (16), bolt adjuster (17) and adjuster

sleeve (18).

7

1

7.

springs (23) from the hold down pins (26). Remove

brake shoes (13), pawl (19) and adjuster assembly (27).

Remove hold down washers (22) and hold down

4

4

8.

cable from parking brake lever.

If servicing rear brakes, disengage parking brake

8

2

6

9.

See Brake Cylinder Service in this section for infor-

3

mation on brake cylinder disassembly, inspection and

assembly procedures.

10.If

needed, remove brake backing plate from vehicle

by removing four cap screws and lock washers.

5

5

Inspection

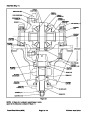

Figure 6

1.

moved for brake service.

Clean and inspect brake drum any time they are re-

1.

2.

3.

4.

Upper shoe spring

Adjuster spring

Lower shoe spring

Hold down washer

5.

6.

7.

8.

Brake shoe

Adjuster assembly

Brake cylinder assy

Pawl

A. Check drum diameter at a minimum of three loca-

tions. Diameter should not exceed the over size limit

cast into the outside of the drum. Replace drum if lim-

it is exceeded.

Workman 3000/4000 Series

Page 7 – 15

Chassis

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Workman 3000, Toro Workman 4000 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)