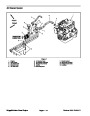

The ring gear (32) and pinon gear (8) are supplied as a

matched set. Both gears are etched for verification with

matching numbers. If a new gear set is being used,

verify that the matching numbers are the same on both

the ring and pinion gear before assembling the front dif-

ferential (Fig. 33).

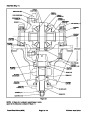

SHIMMING

DIMENSION

The distance from the center line of the ring gear to the

bottom of the pinion gear teeth is 3.750 inches (5.525

cm). This distance represents the best running position

for the gear set (Fig. 32).

MATCHING

NUMBERS

On the end of each pinion gear, there is an etched num-

ber indicated by plus (+), minus (–), or zero (0). This

number indicates a shimming dimension for the best

running position of the gear set. This dimension is con-

trolled by shimming between the the bearing cup (10)

and the carrier assembly (15) (Fig. 33).

Figure 33

When reusing an old ring gear and pinion gear shaft set,

measure the old shim pack thickness and build a new

shim pack to the same thickness. Measure each shim

separately with a micrometer. Add each shim thickness

to get the total shim pack thickness.

For example: If a pinion gear shaft is etched +4, this pin-

ion would require 0.004 inch less shims than a pinion

etched ”0”. By removing shims, the running position is

increased to 3.754 inches. The +4 represents a 0.004

inch increase in the running position. On the other hand:

If a pinion gear shaft is etched –4, this pinion would re-

quire 0.004 inch more shims than a pinion etched ”0”. By

adding shims, the running position is decreased to

If a new gear set is being used, note the (+) or (–) etching

on both the old and new pinion gear shaft. Change the

thickness of the new shim pack to compensate for the

difference between these two dimensions.

For example: If the old pinion gear shaft reads + 2 and

the new gear is –2, add 0.004 inch of shims to the old

shim pack (see Table 1).

3.746

inches. The –4 represents a 0.004 inch decrease

in the running position.

NOTE: All shims (14, 21, and 31) are available in thick-

nesses of 0.003, 0.005, 0.010, and 0.030 inch.

Old Pinion

Marking

–4

New Pinion Marking

–3

–2

–1

0

+1

+2

+3

+4

+4

+3

+2

+1

0

+0.008

+0.007

+0.006

+0.005

+0.004

+0.003

+0.002

+0.001

0

+0.007

+0.006

+0.005

+0.004

+0.003

+0.002

+0.001

0

+0.006

+0.005

+0.004

+0.003

+0.002

+0.001

0

+0.005

+0.004

+0.003

+0.002

+0.001

0

+0.004

+0.003

+0.002

+0.001

0

+0.003

+0.002

+0.001

0

+0.002

+0.001

0

+0.001

0

0

–0.001

–0.002

–0.003

–0.004

–0.005

–0.006

–0.007

–0.008

–0.001

–0.002

–0.003

–0.004

–0.005

–0.006

–0.007

–0.001

–0.002

–0.003

–0.004

–0.005

–0.006

–0.001

–0.002

–0.003

–0.004

–0.005

–1

–2

–3

–4

–0.001

–0.002

–0.003

–0.004

–0.001

–0.002

–0.003

–0.001

–0.002

–0.001

Table 1

1.

If the bearing cone (9) was removed, press new

bearing cone onto the shaft of the pinion gear (8) (Fig.

34).

Figure 34

Workman 4000 Series

Page 10 – 23

Front Wheel Drive (4WD)

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Workman 3000, Toro Workman 4000 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)