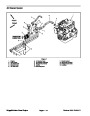

Clutch Disassembly and Inspection (Fig. 20)

Insert clutch alignment tool (see Special Tools) in fly-

wheel pilot bearing hole to keep clutch disk from falling

off (Fig. 21).

3. Install pressure plate. Install and tighten six cap

screws and lock washers a little at a time, working in a

diagonal sequence. Torque screws from 5 to 7 ft--lb (7 to

1.

9

N--m). Remove alignment tool from flywheel bearing.

2.

Loosenpressureplatescrews(Item 10)inadiagonal

sequence.

Clutch Alignment Tool

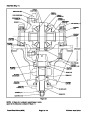

3.

Remove cap screws, washers (Item 11) and pres-

sure plate (Item 12), then slide out the transaxle main

shaft and remove clutch disk (Item 13). Note orientation

of clutch disk as it is removed (Fig. 22).

4.

wear and uneven height. Replace if wear is evident or if

height difference exceeds 0.020 in. (0.5 mm).

Inspect diaphragm spring end of pressure plate for

Figure 21

5.

Check pressure plate surface for wear, cracks and

color change.

Clutch Disc

6.

Check strap plate rivets for looseness and replace

pressure plate if loose.

7.

tact, deterioration due to seizure, adhesion of oil or

grease. Replace clutch disk if damaged.

Checkclutchdiskfacingforlooserivets,unevencon-

Engine

Pressure

Plate Side

Flywheel

Side

8.

Measure rivet sink and replace clutch disk if out of

specification (Fig. 24).

Clutch disk thickness

standard value

0.307 to 0.339 in. (7.8 to 8.6

mm)

Figure 22

Clutch disk rivet sink

0.012 in. (0.3 mm) minimum

Pressure plate

9.

Check for torsion spring play or damage. Replace

clutch disk if necessary.

10.Install

clutch disk on transaxle main shaft. Make sure

clutch slides freely on splines of shaft. Check for exces-

sive play in rotating direction.

Diaphragm spring

Torsion spring

11.

Inspect flywheel surface for stepped wear, streaking

or seizure. Replace if necessary. Clean any oil or rust

fromflywheelsurfacewithlightabrasive.Checkflywheel

runout and replace if runout exceeds 0.005 in. (0.13

mm).

Figure 23

Rivet sink

12.Inspect

flywheel pilot bearing for wear or damage

and replace if necessary.

Installing Clutch Disk and Pressure Plate

1.

use a brush to rub it in. Wipe off any excess grease.

Apply a coating of grease to clutch disk spline, then

2.

Use clutch alignment tool (see SpecialTools) toposi-

tion clutch disk on flywheel.

Figure 24

Workman 3000/4000 Series

Page 6 -- 21 Rev. C

Drive Train

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Workman 3000, Toro Workman 4000 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)