7.

Start the engine, operate at idle speed and rotate the

CAUTION

steering wheel in both directions until air is out of hydrau-

lic system.

Before performing any service or repair on hy-

draulic system components, relieve system

pressure to avoid injury from pressurized hy-

draulic oil. Stop the engine, remove key from the

ignition switch, rotate the steering wheel in both

directions, lower or support the bed and operate

other hydraulic accessories.

8. Stop the engine and check oil level in transaxle (see

Operator’s Manual). Add Dexron III ATF if necessary.

7

8

6

5

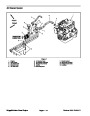

5.

Raise dash to gain access to steering control (Fig.

28):

4

2

A. Remove seven (7) screws (item 2) that secure

hood and dash to frame.

3

B. Remove two (2) cap screws (item 5) and flat

washers (item 4) that secure dash to steering control.

C. Carefully lift dash to allow steering control remov-

al.

6.

Remove steering control valve from vehicle frame by

removing four (4) cap screws.

1

7.

Remove cable ties that secure cover (item 12) over

hydraulic hoses. Remove cover from hoses.

8.

Label and disconnect hydraulic hoses from steering

Figure 28

control valve (refer to Figures 27 and 29). Install caps or

plugs in hoses to prevent contamination and leakage of

hydraulic oil. Install plugs in valve ports.

1.

2.

3.

4.

Hood

5.

6.

7.

8.

Cap screw (2 used)

Screw (7 used)

Well nut (7 used)

Flat washer (2 used)

Knob

Cover

Dash

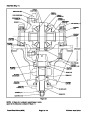

Installation (Fig. 27)

1.

Replace o–rings on hydraulic hoses and fittings. Re-

move caps and plugs from hoses and fittings. Connect

hydraulic hoses to correct steering control valve ports

(refer to Figures 27 and 29). Make sure that hoses are

not twisted while tightening.

5

1

2.

Secure steering control valve to vehicle with four (4)

cap screws.

3.

with cable ties.

Install hydraulic hose cover over hoses and secure

4

2

3

4.

Position dash and hood to frame (Fig. 28). Secure

with seven (7) screws and two (2) cap screws with flat

washers.

Figure 29

5.

tion in the Service and Repairs section of Chapter 7 –

Chassis).

Install steering wheel (see Steering Wheel Installa-

1.

2.

3.

Hyd hose to L port

Hyd hose to R port

Hyd hose to P port

4.

5.

Hyd hose to T port

Hyd hose to E port

6.

Check oil level in transaxle (see Operator’s Manual).

Add Dexron III ATF if necessary.

Workman 3000/4000 Series

Page 9 – 35

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Workman 3000, Toro Workman 4000 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)