5.

end of fuel line to prevent contamination and fuel spill-

age. Position disconnected fuel line away from engine.

Disconnect fuel line from fuel pump on engine. Plug

2

3

6.

Disconnect and label electrical leads that attach to

engine and engine accessories.

4

5

1

7.

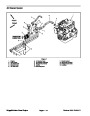

Loosen fasteners that secure hydraulic pump to en-

gine mount (Fig. 5). Rotate pump to allow drive belt (Item

42)

8.

to be removed from pump and engine pulley.

6

Disconnect accelerator cable from throttle lever on

engine. Position accelerator cable away from bracket.

9.

Disconnect choke cable from choke lever on engine.

Remove choke cable from bracket.

10.Remove

all clamps and wire ties that attach wiring

harness, hoses or cables to the engine.

11.

Put blocking under transaxle for support.

Figure 5

1.

2.

3.

Hydraulic pump

Lock nut (2 used)

Engine mount

4.

5.

6.

Pump drive belt

Carriage screw

Cap screw

12.Attach

hoist or block and tackle to engine for support.

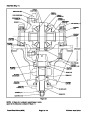

13.Loosen

and remove four (4) lock nuts (Item 37), flat

washers (Item 38) and cap screws (Item 40) that secure

engine to engine mount. Locate and retrieve lock wash-

er (Item 41) from cap screw on right front corner of en-

gine.

5

4

3

14.Remove

secure clutch bell housing to engine (Fig. 6).

four (4) cap screws with lock washers that

2

1

15.Use

a hoist or block and tackle to remove engine

from chassis. One person should operate hoist or block

and tackle and the other person should help guide en-

gine out of chassis. Move engine forward before lifting

to disengage transaxle input shaft from clutch.

6

16.Note

location and retrieve two (2) bushings (Fig. 6,

item 2) from bell housing.

7

17.If

necessary, remove hydraulic pump drive pulley

from stub shaft on flywheel side of engine. Locate and

retrieve woodruff key.

Figure 6

18.If

pressure plate and clutch disc removal is neces-

sary, see Clutch Disassembly and Inspection in Chapter

– Drive Train.

1.

2.

3.

4.

Engine

5.

6.

7.

Cap screw (4 used)

Transaxle

Clutch adapter

Bushing (2 used)

6

Clutch bell housing

Lock washer (4 used)

Flywheel and Pilot Bearing Inspection

1.

Inspect flywheel (Item 33) surface for stepped wear,

streaking or seizure and replace if necessary. Check fly-

wheel runout and replace if runout exceeds .005 in.

(0.13

mm).

2.

Check pilot bearing (Item 30) for smooth rolling and

noise. Check (sealed) bearing for grease leakage. Re-

place bearing if necessary. Remove pilot bearing by

backing out socket head cap screw that attaches fly-

wheel to crankshaft. Do not reuse bearing if removed.

Workman 3100

Kohler Gasoline Engine

Page 5 – 9

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Workman 3000, Toro Workman 4000 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)