Procedure for High Flow Hydraulic Kit (Optional)

Gear Pump Flow and System Relief Pressure Test

8. With Kit switch still in the ON position, watch tester

pressure gauges while slowly closing flow control valve

on the tester until 1500 PSI (103.4 Bar) is obtained on

gauge. Verify that pump speed continues to be 3000

RPM. Record flow meter reading.

1.

Make sure hydraulic oil is at normal operating tem-

perature by operating the vehicle for approximately 10

minutes.

GAUGE READING TO BE: Flow should be approxi-

mately 7.9 GPM (29.9 LPM) at 1500 PSI (103.4 Bar).

2.

Park vehicle on a level surface, raise and support bed

(if installed), shut engine off and engage the parking

brake. After turning engine off, operate all hydraulic con-

trols to relieve hydraulic system pressure.

9. Open tester flow control valve, turn Kit switch OFF

and stop engine.

3.

is adjusted properly (see Kit Installation Instructions).

Make sure that drive belt for High Flow Kit gear pump

10.If pump flow specification is not met, inspect for:

A. Slipping pump drive belt.

CAUTION

B. Worn or stuck relief valve.

C. Pump suction line restriction.

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS, and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

D. Gear pump needs to be repaired or replaced.

11.

To test High Flow Hydraulic system relief pressure:

A. Make sure flow control valve on tester is fully

open.

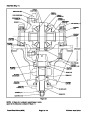

IMPORTANT: Make sure that the oil flow indicator

arrow on the flow meter is showing that the oil will

flow from the pressure coupler, through the tester,

and into the return (tank) coupler (Fig. 19).

B. Start engine and depress accelerator pedal so

engine is running at high idle (3600 + 50 RPM). Turn

Kit switch ON.

4.

With the engine off, install tester with pressure

IMPORTANT: Close flow control valve on tester

only enough to get a system relief pressure read-

ing.

gauges and flow meter in series between the quick dis-

connect couplings. Make sure the tester flow control

valve is open.

C. Watch pressure gauge carefully while slowly clos-

ing the tester flow control valve until the relief valve

opens.

5.

necting the tester.

Make sure the Hydraulic Kit reservoir is full after con-

CAUTION

D. System pressure should be approximately 2000

PSI (137.9 Bar) as the relief valve lifts.

E. Open tester flow control valve, release accelera-

tor pedal to allow engine to return to low idle and turn

Kit switch OFF. Turn off vehicle. Record test results.

The engine must be running to perform hydrau-

lic tests. To guard against possible personal in-

jury, engage parking brake and keep clothing,

hands, feet, face and other parts of the body

away from fan and other moving parts.

12.If

relief pressure is incorrect, inspect for:

A. Slipping pump drive belt.

6.

After installing tester, start engine and run at idle

B. Worn, stuck or out of adjustment relief valve.

speed. Turn hydraulic kit switch ON and check for hy-

draulic leakage from connections. Correct before pro-

ceeding with test.

13.Remove

tester from quick disconnect couplings.

7.

Adjust engine speed with accelerator pedal so High

Flow Kit gear pump speed is 3000 RPM (engine speed

approximately 3600 RPM). Verify pump speed with a

phototac.

Workman 3000/4000 Series

Page 9 – 23

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Workman 3000, Toro Workman 4000 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)