6.

Verify bearing preload and pinion gear shaft (8) rota-

tion as follows:

A. Install coupler flange (19), washer (17), and lock

nut (18) to the shaft of the pinion gear. Torque lock

nut from 75 to 90 ft–lb (102 to 122 N–m).

B. The torque required to rotate the shaft of the pin-

ion gear should be from 7 to 12 in–lb (8 to 14 kg–cm)

(Fig. 39).

C. If the torque required to rotate the shaft of the pin-

ion gear is more than specified in step B, remove lock

nut, washer, coupler flange, bearing cone (22), and

shim (21) from the shaft of the pinion gear. Increase

shim thickness to decrease bearing preload.

Figure 39

D. If the torque required to rotate the pinion gear

shaft is less than specified in step B, remove lock nut,

washer, coupler flange, bearing cone (22), and shim

(21)

from the pinion gear shaft. Decrease shim thick-

ness to increase bearing preload.

E. Install shim, bearing cone, coupler flange, wash-

er, and lock nut to the pinion gear shaft. Torque lock

nut from 75 to 90 ft–lb (102 to 122 N–m).

F. The torque required to rotate the pinion gear shaft

should be from 7 to 12 in–lb (8 to 14 kg–cm). If the

torque to rotate the pinion gear shaft does not meet

specification, repeat steps C or D and E as neces-

sary.

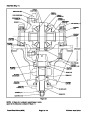

Figure 40

SPLINES

G. If the torque required to rotate the shaft of the pin-

ion gear shaft is as specified in step B or F, remove

lock nut, washer, coupler flange, bearing cone (22)

from the shaft of the pinion gear. Press new oil seal

(20)

into the carrier assembly (15) (Fig. 40).

H. Apply No. 2 Permatex sealant or equivalent to the

splines of the pinion gear. Make sure not to get

sealant on the oil seal (20) (Fig. 41).

Figure 41

I. Install flange coupler, washer, and lock nut back

onto the pinion gear. Torque lock nut from 75 to 90

ft–lb (102 to 122 N–m).

7.

Install thrust washers (7) to pinion gear shafts (6),

and thrust washers (4) to side bevel gears (5) (Fig. 42).

A. Place gears and washers into the differential

case (27).

B. Rotate both sets of gears simultaneously until the

pinion shaft (25) can be inserted through the differ-

ential case, thrust washers, and pinion gear shafts.

C. Install pinion shaft into the differential case and

pinion gear shafts. Secure shaft with roll pin (28).

Figure 42

Workman 4000 Series

Page 10 – 25

Front Wheel Drive (4WD)

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Workman 3000, Toro Workman 4000 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)