16.Put

blocking under engine for support. Support trans-

axle with a floor jack or suspend transaxle from vehicle

frame rails.

17.Remove

transaxle isolation mounts and mount

brackets (Fig. 17).

18.Remove

side–to–side to disconnect each drive shaft from axle

shafts on transaxle.

drive shaft clamp bolts, then slide transaxle

1

2

2

19.Remove

cap screws securing clutch bell housing to

engine. Note location of washers and harness brackets.

20.Carefully

input shaft from clutch. Use floor jack to lower transaxle

and slide out rear of vehicle under the frame.

pull transaxle back to disengage transaxle

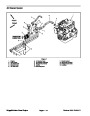

Figure 17

1.

Mounting brackets

2.

Drive shaft

21.Note

ing.

location and retrieve dowel pins from bell hous-

4

Installation

1.

To install the transaxle, perform Transaxle Removal

procedure in reverse order noting the following:

3

IMPORTANT: Workman 3100 (air cooled, gasoline

engine) vehicles require application of silicone seal-

ant to mating surface of bell housing and clutch

adapter plate on engine. This will prevent dirt and

debris from getting into bell housing and damaging

clutch or release bearing.

2

1

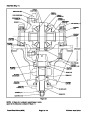

Figure 18

A. When installing driveshafts to transaxle, align

mounting holes in driveshaft with relief in transaxle

shaft. Install cap screws, hardened washers, and

flange nuts to secure driveshaft to transaxle shaft.

Torque fasteners from 35 to 42 ft–lb (47 to 57 N–m).

1.

2.

First–Reverse

High–Low

3.

4.

2nd–3rd

PTO clutch

200

to 280 in–lb

to 31.6 N–m)

200

(22.6 to 31.6 N–m)

to 280 in–lb

(22.6

B. Apply Loctite #242 (or equivalent) to the threads

of cap screws used to secure the control cable sup-

port bracket to the transaxle.

C. Before installing two shift levers and shift arm

onto transaxle shafts, thoroughly clean shafts and

apply Loctite #680 to threads and tapers of shafts.

Secure by torquing nut from 200 to 280 in–lb (22.6 to

Apply Loctite 680

to threads and tapers

31.6

N–m) while holding lever to prevent torque

transfer into transaxle (Fig. 19).

2.

Install a new hydraulic oil filter and fill transaxle with

the correct oil (see Operator’s Manual). Check for oil

leaks and repair as necessary.

3.

differential lock cable (see Operator’s Manual).

Adjust clutch pedal, shift cables, high–low cable and

Figure 19

4.

If equipped with PTO, adjust PTO cable (see PTO

Cable Adjustment in the Adjustments section of this

chapter).

Drive Train

Page 6 – 18

Workman 3000/4000 Series

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Workman 3000, Toro Workman 4000 |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)