7.

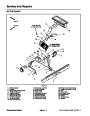

Support gear pump assembly to prevent it from fal-

ling.

3

RIGHT

FRONT

8.

Remove two (2) cap screws and washers securing

4

gear pumptopiston pump. Remove gear pump,coupler

(item 9), spacer (item 17) and O--rings (item 16) from

machine.

5

9.

If hydraulic fittings are to be removed from gear

pump, mark fitting orientation to allow correct assembly.

Remove fittings from pump and discard O--rings.

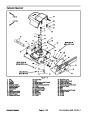

Installation (Fig. 56)

1

1.

If fittings were removed from gear pump, lubricate

6

and place new O--rings onto fittings. Install fittings into

pump ports using marks made during the removal pro-

cess to properly orientate fittings. Tighten fittings (see

Hydraulic Fitting Installation in the General Information

section of this chapter).

2

7

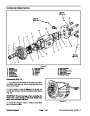

Figure 57

1.

2.

3.

4.

5.

6.

7.

Supply hose to deck manifold P1 port

Supply hose to deck manifold P2 port

Supply hose to fan manifold P2 port

Supply hose to fan manifold P1 port

Suction hose from filter manifold

Suction hose from reservoir

2.

oil. Position O--rings on gear pump and pump spacer

flanges.

Lubricate new O--rings(item 16)with cleanhydraulic

Supply hose for charge circuit

3.

Slide coupler (item 9) onto the piston pump output

shaft.

4.

Position pump spacer (item 17) to gear pump. Align

gear teeth and slide gear pump input shaft into coupler.

Secure gear pump to piston pump with two (2) cap

screws and flat washers.

5.

Remove caps and plugs from hydraulic hoses and

fittings. Install hoses to gear pump (see Hydraulic Hose

and Tube Installation in the General Information section

of this chapter).

6.

Replace hydraulic filter and fill hydraulic reservoir

with new hydraulic oil.

7.

Disconnect engine run solenoid electrical connector

to prevent engine from starting. Prime the hydraulic

pump by turning the ignition key switch to start and

crankingtheengineforten(10)seconds.Letstartercool

and then repeat cranking procedure again.

8.

start the engine and check for proper operation.

Connect engine run solenoid electrical connector,

9.

Properly fill hydraulic system (see Charge Hydraulic

System in this section).

10.Stop

engine and check for hydraulic oil leaks. Check

hydraulic reservoir oil level.

11.

Lower and secure seat.

Groundsmaster 4500--D/4700--D

Page 4 -- 73

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 30857, Toro Groundsmaster 30858, Toro Groundsmaster 4500 D, Toro Groundsmaster 4700 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)