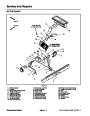

Removal (Fig. 64)

4

75 ft--lb

25

33.9 N--m)

ft--lb

(101

N--m)

NOTE: The ports on the manifolds are marked for easy

identification of components. Refer to the Hydraulic

Schematics in Chapter 9 -- Foldout Drawings to identify

the function of the hydraulic lines and cartridge valves

at each port.

9

(

8

2

6

7

5

5

10

1.

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

Read the General Precautions for Removing and

5

(68

0 ft--lb

N--m)

6

11

2.

manifold removal, thoroughly clean exterior ofmanifold.

To prevent contamination of hydraulic system during

2

12

4

3.

If 4WD/2WD control manifold is being removed, la-

15

bel wire harness electrical connectors that attach to

manifold components. Disconnect harness electrical

connectors from the solenoid valve coil and electrical

sensors (pressure and temperature).

4

3

2

13

2

(27.1

0 ft--lb

N--m)

1

14

4.

Disconnect hydraulic lines from manifold being re-

moved and put caps or plugs on open hydraulic lines

andfittings. Labeldisconnected hydraulic lines forprop-

er assembly.

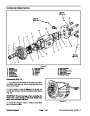

Figure 65

1.

2.

3.

4.

5.

6.

7.

8.

4WD/2WD manifold

9.

Check fitting

O--ring

10. O--ring

45o fitting

11. O--ring

O--ring

12. Straight fitting

13. O--ring

5.

Remove hydraulic manifold from the frame using

90o fitting

Figure 64 as guide.

Straight fitting

O--ring

14. Test fitting

15. Dust cap

6.

If hydraulic fittings are to be removed from control

O--ring

manifold,markfittingorientation toallowcorrectassem-

bly (Figure 65 or 66). Remove fittings from manifold and

discard O--rings.

25

(33.9

ft--lb

N--m)

50

(68 N--m)

ft--lb

6

Installation (Fig. 64)

20

(27.1

ft--lb

N--m)

5

1.

If fittings were removed from control manifold, lubri-

7

4

cate and place new O--rings onto fittings. Install fittings

into manifold ports using marks made during theremov-

al process to properly orientate fittings. Tighten fittings

(see Hydraulic Fitting Installation in the General Infor-

mation section of this chapter). Refer to Figure 65 or 66

for fitting installation torque.

4

8

11 10

9

2

3

1

17

12

8

2.

64

Install hydraulic manifold to the frame using Figure

as guide.

3.

Remove caps and plugs from fittings and hoses.

4

Properly connect hydraulic lines to manifold (see Hy-

draulic Hose and Tube Installation in the General Infor-

mation section of this chapter).

14

15

13

16

8

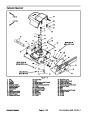

Figure 66

4.

wire harness electrical connectors to the solenoid valve

coil and electrical sensors.

If4WD/2WD control manifoldwasremoved,connect

1.

Filtration manifold

10. 90o fitting

11. O--ring

2.

3.

4.

5.

6.

7.

8.

9.

O--ring

90o fitting

O--ring

Straight fitting

O--ring

Straight fitting

O--ring

O--ring

12. Test fitting

13. Dust cap

14. Tee fitting

5.

quired.

Fill hydraulic reservoir with hydraulic fluid as re-

15. O--ring

16. 90o fitting

17. O--ring

Groundsmaster 4500--D/4700--D

Page 4 -- 81

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 30857, Toro Groundsmaster 30858, Toro Groundsmaster 4500 D, Toro Groundsmaster 4700 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)