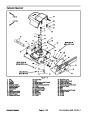

Lower Cutting Decks: Groundsmaster 4500--D

A four section gear pump is coupled to the piston (trac-

tion) pump. Gear pump section P3 supplies hydraulic

flowtoboththeliftcontrolmanifoldandthesteeringcon-

trol valve. Hydraulic flow from this pump section is deliv-

ered to the circuits through a proportional flow divider

located in the fan control manifold. Maximum lift/lower

circuitpressureislimitedto1600PSI(110bar)byarelief

valve (R1) inthe liftcontrol manifold. Lift circuit pressure

can be monitored at lift control manifold test fitting G1.

Counterbalance

Once the cutting decks are fully lowered, the lift control

manifold proportional relief valve (TS) maintains back

pressure (counterbalance) on the deck lift cylinders.

This counterbalance pressure transfers cutting deck

weight to the machine to improve traction.

A pressure sensor located in the 4WD/2WD control

manifold is used by the TEC--5002 controller as an input

to determine traction circuit pressure. Based on this

sensor input, a PWM (Pulse Width Modulation) signal

from the TEC--5002 controller is provided to the propor-

tional relief valve (TS) to maintain counterbalance pres-

sure.

On the Groundsmaster 4500--D, a single lift switch on

the console arm is used to raise and lower the five (5)

cutting decks (Fig. 10).

When the cutting decks are in a stationary position (not

raising or lowering), lift circuit flow from gear pump sec-

tion P3 bypasses the lift cylinders through the lift control

manifold solenoid valve S5 (de--energized) and propor-

tional relief valve TS. Return flow from the manifold is

routed to the oil filter and traction charge circuit.

NOTE: The operator must be in the operator seat in or-

der to lower the cutting decks. Also, when in high speed

(2WD),

the cutting decks will not lower.

Cutting Deck Lower

1

To lower the five (5) cutting decks on a Groundsmaster

4500--D,

the front of the lift switch is depressed. The

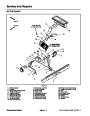

Figure 10

switchactsasaninputtotheTEC--5002controllerwhich

then provides an electrical output to solenoid valve S6

in the liftcontrol manifold. Thisenergized solenoid valve

shifts to allow a passage for oil flow from the rod ends

ofthefive(5)deckliftcylinders.Theweightofthecutting

decks causes the lift cylinders to extend and lowers all

of the cutting decks. An orifice in the lift control manifold

restricts oil flow from the lift cylinders to control deck

drop speed. Additionally, an orifice in the junction man-

ifold further controls the lowering speed of the #1 deck.

1. Lift switch (#1 to #5)

#4

#1

#5

#

2

#3

Whenthedeck switch isreleased, thesolenoid valve S6

is de--energized and the lift cylinders and cutting decks

are held in position.

Cutting Deck Float

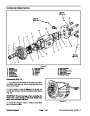

GM--4500 CUTTING DECK LOCATIONS

Cutting deck float allows the fully lowered cutting decks

to follow ground surface contours. On aGroundsmaster

Figure 11

4500--D,

lift control manifold solenoid valve S6 is ener-

gized for deck float when the decks are fully lowered.

This energized solenoid provides an oil passage to and

from the lift cylinders to allow cylinder and cutting deck

movement while mowing.

Groundsmaster 4500--D/4700--D

Page 4 -- 17

Hydraulic System

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 30857, Toro Groundsmaster 30858, Toro Groundsmaster 4500 D, Toro Groundsmaster 4700 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)