Glow and Main Power Relays

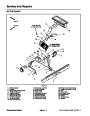

The glow and main power relays are located at the pow-

er center behind the operator seat (Fig. 34). These re-

lays are attached to the wire harness with a four (4) wire

connector (Fig. 35).

7. Disconnect voltage and test leads from the relay ter-

minals.

8.

Secure relay to mounting bracket and connect wire

harnessconnectortorelay.Installcovertopowercenter.

The glow relay is used to provide current to the engine

glowplugswhenenergizedbytheTEC--5002controller.

The TEC--5002 controls and monitors the operation of

the glow relay.

9.

nect negative (--) cable to battery (see Battery Service

in the Service and Repairs section of this chapter).

Connect positive (+) cable to battery and then con-

The main power relay is used to provide current to the

TEC controllers and most of the fuse protected circuits

(headlights, operator seat, power point and optional

electric equipment). When the ignition switch is in the

ON or START position, the main power relay is ener-

gized.

3

1

1

2

Testing

4

1.

decks, stop engine, engage parking brake and remove

key from the ignition switch.

Park machine on a level surface, lower cutting

2.

To make sure that machine operation does notoccur

unexpectedly, disconnect negative (--) cable from bat-

tery and then disconnect positive (+) cable from battery

(see Battery Service in the Service and Repairs section

of this chapter).

5

3.

be tested.

Remove cover from power center and locate relay to

6

5

Figure 34

4.

Disconnect wire harness connector from relay. Re-

move relay from mounting bracket for testing.

1.

2.

3.

Lock nut

Main power relay

Glow relay

4.

5.

6.

Start relay

Flange head screw

Mounting bracket

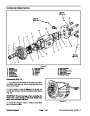

NOTE: Prior to taking small resistance readings with a

digital multimeter, short the meter test leads together.

The meter will display a small resistance value (usually

0.5

ohms or less). This resistance is due to the internal

86

85

87

30

resistance of the meter and test leads. Subtract this val-

ue from from the measured value of the component you

are testing.

30

85

86

87

5.

Using a multimeter, verify that coil resistance be-

tween terminals 86 and 85 is approximately 72 ohms.

6.

Connectmultimeter (ohmssetting) leadstorelayter-

Figure 35

minals 30 and 87. Ground terminal 86 and apply +12

VDC to terminal 85. The relay should make and break

continuity between terminals 30 and 87 as +12 VDC is

applied and removed from terminal 85.

Electrical System

Page 5 -- 26

Groundsmaster 4500--D/4700--D

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Groundsmaster 30857, Toro Groundsmaster 30858, Toro Groundsmaster 4500 D, Toro Groundsmaster 4700 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)