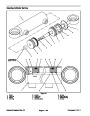

Inspection (Fig. 46)

12.Replace body if the inside diameter of the gear pock-

ets exceeds 1.713 in. (43.5 mm).

1.

Remove all nicks and burrs from all parts with an

emery cloth.

13.Make sure both plugs are secure if they or the back-

plate is not being replaced.

CAUTION

Reassembly (Fig. 46)

1.

If replacing the relief valve assembly, install ball,

spring, shim, O−ring, and plug into the backplate. Hand

tighten plug and then torque from 10 to 12 ft−lb (13.6 to

Use eye protection such as goggles when using

compressed air.

16.3

N−m).

2.

pressed air.

Clean all parts with solvent. Dry all parts with com-

2.

groove on the front plate.

Coat O−ring lightly with petroleum jelly and install in

3.

way.

Inspect drive gear shaft for a broken or chipped key-

3.

ets of the body. Install alignment pin into body.

Apply a thin coat of petroleum jelly to both gear pock-

4.

ing points and seal area for rough surfaces and exces-

sive wear.

Inspect drive gear and idler gear shafts at the bush-

4.

alignment pin is engaged.

Align matchmarks and slip body onto front plate until

5.

and slip into front plate bushings.

Dip idler gear and drive gear into clean hydraulic oil

5.

in the bushing area measures less than 0.748 in. (19.0

mm). A single gear may be replaced separately.

Replace drive gear or idler gear if the shaft diameter

6.

Coat O−ring lightly with petroleum jelly and install in

groove on the back plate.

6.

The drive gear and idler gear face should be free of

excessive scoring and wear.

7.

8.

Install alignment pin into back plate.

7.

Replace drive gear or idler gear if gear width is less

Align matchmarks and slip back plate over gear

than 1.140 in. (29.96 mm).

shafts onto body until alignment pin is engaged.

8.

both sides of the gear for both the drive gear and idler

gear.

Make sure that retaining rings are in the grooves on

9.

crisscross pattern from 25 to 28 ft−lb (33.9 to 38.0 N−m).

Hand tighten cap screws. Torque cap screws in a

10.Place

washer over the drive shaft into the front plate

9.

Break sharp edges of gear teeth with emery cloth.

housing. Apply a liberal coat of hydraulic oil to the oil

seal. Install oil seal over the drive shaft being careful not

to cut the rubber seal lips.

10.Replace

diameters exceed 0.755 in. (19.2 mm). The bushings

are not available as replacement items.

backplate and frontplate if bushing inside

11.

Place 1−1/16 inch O.D. sleeve over the drive shaft

and press in the oil seal until the retaining ring groove

appears.

11.

The face of the backplate and frontplate should be

free of excessive scoring. Replace if scoring a depth of

in. (0.038 mm).

0.0015

12.Press

retaining ring into the housing using the sleeve

until it seats in the groove.

Reelmaster 3100−D

Hydraulic System (Rev. C)

Page 4 − 75

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Reelmaster 3100-D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)