Service and Repairs

Greasing Bearings, Bushings, and Pivot Points

Each cutting unit has 9 grease fittings (with an optional

front roller installed) that must be lubricated regularly

with No. 2 general purpose lithium base grease.

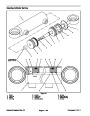

Grease Fitting Locations and Quantities

Each bedknife adjuster has 1 fitting (Fig. 15). Each reel

bearing housing has 2 fittings. Each front and rear roller

has 2 fittings, one on each end of the roller (Fig. 16).

NOTE: Lubricate only one reel bearing grease fitting on

each end of cutting unit.

Figure 15

Grease every 50 hours

IMPORTANT: Lubricate cutting units immediately

after washing. This helps purge water out of bear-

ings and increases bearing life.

1.

Wipe each grease fitting with a clean rag.

IMPORTANT: Do not apply too much pressure or

grease seals will be permanently damaged.

2.

3.

Apply grease until pressure is felt against the handle.

Wipe excess grease away.

Figure 16

Grease every 8 hours

Reelmaster 3100−D

Page 7 − 13

Cutting Units

Product Specification

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Reelmaster 3100-D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |