Fuel Pump

The fuel pump is attached to the frame just outboard of

the fuel injection pump.

2

4

Operational Test

1

1.

Park machine on a level surface, lower cutting units,

stop engine, and engage parking brake.

2.

solenoid to prevent the engine from firing.

Disconnect electrical connector from the fuel stop

3.

filter.

Disconnect fuel hose (pump discharge) from the fuel

3

4.

free of obstructions.

Make sure fuel hoses attached to the fuel pump are

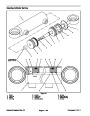

Figure 19

1.

2.

Fuel pump

Fuel hose (discharge)

3.

4.

Fuel filter

Fuel stop solenoid

5.

Place fuel hose (pump discharge) into a large, grad-

uated cylinder sufficient enough to collect 1 liter (33.8

fluid ounces).

Fuel Pump Specifications

Fuel pump specifications for machines with serial num-

bers below 240000000 are as follows:

IMPORTANT: When testing the fuel pump, DO NOT

turn ignition switch to START.

Note:

Conversion Kit will have the same fuel pump as ma-

chines with serial numbers above 280000000.

Machines that are equipped with a Biodiesel

Pump Capacity

Pressure

13.5 fl oz/min (400 ml/min)

5.4 psi (37.3 kPa)

1.5 amp

Current Draw

6.

Collect fuel in the graduated cylinder by turning igni-

tion switch to the RUN position. Allow pump to run for

time listed below, then return switch to OFF.

Fuel pump specifications for machines with serial num-

bers from 240000000 to 270999999 are as follows:

A. For machines with serial numbers below

Pump Capacity

Pressure

23.5 fl oz/min (700 ml/min)

3.3 PSI (22.8 kPa)

0.9 amp

230999999,

the amount of fuel collected in the grad-

uated cylinder should be approximately 6.8 fl oz

ml) after thirty (30) seconds.

(200

Current Draw

B. For

machines

with

serial

numbers

from

240000000

lected in the graduated cylinder should be approxi-

mately 11.8 fl oz (350 ml) after thirty (30) seconds.

to 270999999, the amount of fuel col-

Fuel pump specifications for machines with serial num-

bers above 280000000 are as follows:

Pump Capacity

Pressure

64 fl oz/min (1.9 liters/min)

7 PSI (48.3 kPa)

2.0 amp

C. For machines with serial numbers above

280000000,

the amount of fuel collected in the grad-

uated cylinder should be approximately 16 fl oz (475

ml) after fifteen (15) seconds.

Current Draw

7.

Replace fuel pump as necessary. Install fuel hose

(pump discharge) to the fuel filter.

8.

Reconnect electrical connector to the fuel stop sole-

noid.

9.

Prime fuel system.

Reelmaster 3100--D

Page 5 -- 37

Rev. E

Electrical Systems (Rev. C)

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Reelmaster 3100-D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)