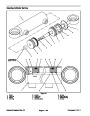

Install New Seals and Bearings on Full or Wiehle

Roller

Install New Seals and Bearings on Sectional Roller

1.

Make sure all parts are clean prior to installing bear-

1.

Make sure all parts are clean prior to installing bear-

ings and seals.

ings and seals.

2.

Press two bearing cups into each sectional roller.

2.

seal faces the inside of the roller. Press an inner seal into

each end of the roller.

On the full roller, make sure cupped side of the inner

Make sure narrow end of taper faces the inside of the

roller.

3.

Secured sectional roller shaft in a vise. Make sure

3.

Make sure narrow end of the taper on the bearing

shaft is level.

cup faces the inside of the roller. Press a cup into each

end of the roller.

4.

lithium base grease.

Pack all bearing cones with No. 2 general purpose

4.

Keep roller level and secured roller in a vise.

NOTE: Install bearing cone with the seal into the end of

5.

If assembling a full roller, fill the inside of roller tube

the roller that faces the inner part of the shaft.

with 6 oz. (170 gm) of SAE 90 oil.

5.

On both rollers, install a bearing cone into the bear-

6.

Pack both bearing cones with No. 2 general purpose

ing cup at each end of the roller.

lithium base grease.

6.

Install outer seal onto the end of each roller. Make

7.

Install a bearing cone into the bearing cup at each

sure the hard surface of seal faces out.

end of the roller.

7.

8.

Tighten each nut to seat both bearings of each roller.

Roller should be rotated to seat both bearings.

Slide each roller onto the shaft.

8.

Position outer seal to the roller with the hard surface

Install adjustment nut onto each end of the shaft.

of seal facing out. Press a seal onto each end of the roll-

er.

9.

er.

Slide roller shaft through the bearing cones and roll-

9.

Back off both adjustment nuts to allow the rollers to

spin freely. Tighten both adjustment nuts again so there

is no bearing end play and rolling torque does not ex-

ceed 5 in−lb (0.57 N−m).

10.Install

both bearings. Roller should be rotated to seat both

bearings.

remaining adjustment nut and tighten it to seat

10.Grease

both bearings (see Greasing Bearings,

11.

Back off both adjustment nuts to allow the roller to

Bushings, and Pivot Points).

spin freely. Tighten both adjustment nuts again so there

is no bearing end play and rolling torque does not ex-

ceed 5 in−lb (0.57 N−m).

12.Grease

both bearings (see Greasing Bearings,

Bushings, and Pivot Points).

Reelmaster 3100−D

Page 7 − 23

Cutting Units

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Reelmaster 3100-D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)