8.

51)

Install rotary handle (Fig. 52) (manifold shown in Fig.

:

D. Pull spool up and out of manifold. Remove O--

rings and back--up ring from spool.

A. Placehandlebaseonflowcontrolvalve andposi-

tion alignment mark on base with number 1 on man-

ifold. Secure base with two (2) set screws. Apply a

light coating of grease to chamfer on top of base to

ease seal installation.

E. Discard removed O--rings and back--up rings.

Visually inspect the spool and manifold port for dam-

2.

age to the sealing surfaces and contamination.

3.

Install spool into mow manifold:

B. Make sure that sleeve bearing is in handle cap. If

necessary, press sleeve bearing into cap. Install lip

seal on cap with seal lip facing down.

A. Install O--rings and back--up ring to upper

grooves on spool. Apply a light coating of grease to

O--rings.

C. Place bushing onto cartridge valve stem. Use a

small amount of grease to keep bushing toward the

top of the valve stem.

B. Carefully push spool down into mow manifold

port until lower O--ring and back--up ring groove is

exposed on bottom of manifold. Install lower O--ring

and back--up ring to spool. Apply a light coating of

grease to O--ring.

D. Place compression spring and detent pin into

handle cap. Use a small amount of grease to hold

detent pin in place.

C. Carefully raise mow/backlap spool until upper re-

taining ring groove on spool is exposed on top of

manifold. Install upper retaining ring.

E. Make sure that flow control valve is closed by ro-

tating valve stem fully clockwise. During handle

installation, DO NOT rotate valve stem or speed ad-

justment will be incorrect.

D. Push mow/backlap spool down and install lower

retaining ring to spool.

F. Press handle cap onto valve stem with arrow on

cappointingtonumber9onmanifold.Makesurethat

detent pin and spring stay positioned in cap.

E. If handle was removed from spool, position spool

so handle location of spool is between stop pins. Ap-

ply Loctite 603 Retaining Compound (or equivalent)

to threads on handle and install handle into spool.

G. While pressing on the cap to keep the lip seal in

place, rotate cap in a clockwise direction until the ar-

row on the cap aligns with number 1 on the manifold.

By rotating the cap clockwise, the valve will remain

closed. Install screw to retain cap.

F. Place ball and dowel pin in backlap switch man-

ifold port. Install new O--ring onto backlap switch.

Thread backlap switch into port and torque 15 ft--lb

(20

N--m).

H. Make sure that alignment marks oncap andbase

areinlineandthatarrowoncapispointingtonumber

2

3

4

1

on manifold. Tighten two (2) set screws to secure

1

Loctite 603

handle cap.

5

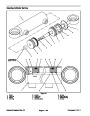

Mow/Backlap Spool (Fig. 53) (Reel Manifold Shown

in Fig. 51)

6

1.

Remove spool from mow manifold:

A. Remove backlap switch from mow manifold be-

fore removing mow/backlap spool. Remove dowel

pin and ball from manifold port after switch is re-

moved. Remove and discard O--ring from switch.

B. Remove lower retaining ring from mow/backlap

spool. Raise mow/backlap spool to allow access to

retaining ring on upper end of spool. Remove upper

retaining ring.

4

3

1

C. Push spool down until O--ring and back--up ring

are exposed on bottom of mow manifold. Remove

lower O--ring and back--up ring from spool.

Figure 53

4.

5.

6.

1.

2.

3.

Retaining ring

O--ring

Back--up ring

O--ring

Spool handle

Rotary spool

Hydraulic System (Rev. C)

Rev. E

Reelmaster 3100--D

Page 4 -- 82

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Reelmaster 3100-D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)