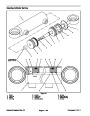

Roller Removal and Installation

Note:

This section can be used for both the front and

rear rollers.

Roller Removal

1.

Remove both height−of−cut pins and hairpin cotters

from each roller bracket.

2

2.

Remove both locknuts from the capscrews securing

each angle bracket to the cutting unit.

1

3.

the cutting unit.

Remove capscrews from both angle brackets and

5

4.

brackets from the cutting unit.

Separate roller assembly, roller brackets, and angle

6

7

4

5.

Remove roller brackets from the roller assembly.

10

3

Roller Installation

8

11

9

1.

Inspect flanged bushing and bushings for wear; re-

place if necessary.

Figure 27

Note:

face inside toward the roller when the roller bracket is

installed onto the cutting unit.

The flanged end of the flanged bushing must

1.

2.

3.

4.

5.

6.

Height−of−cut pin

Hairpin cotter

Roller bracket

Lock nut

Capscrew

Angle bracket

7.

8.

9.

10. Carriage bolt

11. Lock nut

Front roller assembly

Flanged bushing

Bushing

Note:

A soft hammer may be needed to tap the roller

bracket into position on the hex adjustment nut of the

roller.

6.

the cutting unit. Secure roller brackets and angle brack-

ets to the cutting unit with capscrews.

Mount roller, roller brackets, and angle brackets to

2.

Insert smaller diameter roller shaft into the flanged

bushing, bushing, and roller bracket. Make sure hex of

the roller bracket mates with the hex adjustment nut

on the roller.

7.

Install both height−of−cut pins and hairpin cotters.

8.

Install both locknuts to the capscrews, and secure

each angle bracket to the cutting unit.

3.

Insert the other end of the roller shaft into the other

bushing and roller bracket. Make sure hex of the roller

bracket mates with the hex adjustment nut on the

roller.

9.

Both Rollers).

Adjust roller level (see Height−of−Cut and Leveling

4.

Hold one roller bracket stationary and use the other

bracket as a wrench to loosen or tighten bearing clear-

ance. The roller must not exceed 5 in−lb (0.57 N−m) rol-

ling torque and have no bearing end play.

5.

Make sure roller brackets are aligned prior to instal-

ling them onto the cutting unit. If necessary after bearing

adjustment, align roller brackets as follows:

A. Remove roller bracket on the side with the

flanged bushing.

B. Replace roller bracket so it is aligned to within

+

one hex flat of the roller adjustment nut.

C. Align both roller brackets.

Reelmaster 3100−D

Page 7 − 21

Cutting Units

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Reelmaster 3100-D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)