Bleed Fuel System

1.

Park machine on a level surface, lower cutting units,

stop engine, and engage parking brake.

2.

Make sure fuel tank is at least half full. Gain access

to the engine.

2

DANGER

1

Because diesel fuel is highly flammable, use cau-

tion when storing or handling it. Do not smoke

while filling the fuel tank. Do not fill fuel tank

while engine is running, hot, or when machine is

in an enclosed area. Always fill fuel tank outside

and wipe up any spilled diesel fuel before start-

ing the engine. Store fuel in a clean, safety−ap-

proved container and keep cap in place. Use die-

sel fuel for the engine only; not for any other pur-

pose.

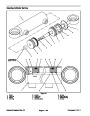

Figure 13

1.

Air bleed screw

2.

Injection pump

4.

Turn key in ignition switch to the ON position. The

electric fuel pump will begin operation and force air out

around the air bleed screw. Leave key in the ON position

until a solid stream of fuel flows out around the air bleed

screw. Tighten screw and turn key to OFF.

3.

Open air bleed screw on the fuel injection pump.

IMPORTANT: The engine should normally start af-

ter the above bleeding procedures are followed.

However, if the engine does not start, air may be

trapped between injection pump and injectors (see

Bleed Air from Fuel Injectors).

Bleed Air from Fuel Injectors

IMPORTANT: This procedure should be used only if

the fuel system has been purged of air through nor-

mal priming procedures (see Bleed Fuel System)

and engine will not start.

2

1

1.

stop engine, and engage parking brake.

Park machine on a level surface, lower cutting units,

3

DANGER

Because diesel fuel is highly flammable, use cau-

tion when storing or handling it. Do not smoke

while filling the fuel tank. Do not fill fuel tank

while engine is running, hot, or when machine is

in an enclosed area. Always fill fuel tank outside

and wipe up any spilled diesel fuel before start-

ing the engine. Store fuel in a clean, safety−ap-

proved container and keep cap in place. Use die-

sel fuel for the engine only; not for any other pur-

pose.

Figure 14

1.

2.

No. 1 injector nozzle

No. 2 injector (behind

hose)

3. No. 3 injector nozzle

3.

Move throttle to FAST position.

4.

Turn ignition switch to START and watch fuel flow

around connector. Turn key to OFF when solid flow is

observed. Tighten pipe connector securely to the injec-

tor nozzle.

2.

Loosen pipe connection to the No. 1 injector nozzle

and holder assembly.

5.

Repeat steps on the remaining injector nozzles.

Reelmaster 3100−D

Page 3 − 9

Kubota Diesel Engine

| Categories | Lawn Mower Manual, Sprinkler and Irrigation Manuals, Toro Sprinkler and Irrigation Manuals |

|---|---|

| Tags | Toro Reelmaster 3100-D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Product Brand | Toro. Customer Service Representatives are available by phone:

Monday - Friday 7:30 a.m. to 9:00 p.m. (CDT) - Saturday 8:00 a.m. to 8:00 p.m. (CDT) - Sunday 10:00 a.m. to 8:00 p.m. (CDT)

Canada 1-888-225-4886 USA 1-888-384-9939, Lawn Mower |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)