5.

Visually inspect cartridge valve for damaged sealing

7. Reinstall the cartridge valve:

surfaces and contamination.

A. Lubricate new seal kit components with clean hy-

draulic oil and install on valve. The o--rings, sealing

rings, and backup rings must be arranged properly

on the cartridge valve for proper operation and seal-

ing.

A. Contamination may cause valves to stick or hang

up.Contaminationcanbecomelodgedinsmallvalve

orifices or seal areas causing malfunction.

B. If valve sealing surfaces appear pitted or dam-

aged, the hydraulic system may be overheating or

there may be water in the system.

IMPORTANT: Use care when handling the valvecar-

tridge. Slight bending or distortion of the stem tube

can cause binding and malfunction.

CAUTION

B. Thread cartridge valve carefully into manifold

port. The valve should go in easily without binding.

C. Torquecartridgevalveusingadeepsockettoval-

ue identified in manifold illustration.

Use eye protection such as goggles when using

compressed air.

D. If cartridge is solenoid operated, carefully install

solenoid coil to the cartridge valve. Apply “Loctite

6.

Clean cartridge valve using clean mineral spirits.

Submerge valve in clean mineral spirits to flush out con-

tamination.Particlesasfineastalcumpowdercanaffect

the operation of high pressure hydraulic valves. If car-

tridgedesignallows,useawoodorplasticprobetopush

the internal spool in and out 20 to 30 times to flush out

contamination. Be extremely careful not to damage car-

tridge. Use compressed air for cleaning.

242”

or equivalent to the threads ofthe valve. Torque

nut to value identified in manifold illustration.

8.

If problems still exist, remove valve and clean again

or replace valve.

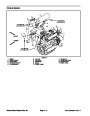

JEM MANIFOLD

10

13

35

ft--lb

13

REAR

DOWN

(47

N--m)

11

6

50

ft--lb

25

(34

ft--lb

N--m)

(67 N--m)

1

0

1

4

10

11

8

7

1

13

13

9

2

10

UP

FRONT

3

5

11

20

(27

ft--lb

N--m)

PLUG TORQUE

10

5

(6.7

ft--lb

#4 Zero Leak: 20 ft--lb (27 N--m)

#6 Zero Leak: 25 ft--lb (34 N--m)

N--m)

11

#8

Zero Leak: 50 ft--lb (67 N--m)

12

Figure 51

1.

2.

3.

4.

5.

Manifold body

Solenoid valve (port SV)

Solenoid coil

Check valve (port CV)

Nut

6.

7.

8.

9.

Directional valve (ports PD1 & PD2)

Pressure reducing valve (port PR)

Relief valve (port RV)

10. #4 zero leak plug with O--ring

11. #6 zero leak plug with O--ring

12. Orifice (.050)

Orifice (.030)

13. #8 zero leak plug with O--ring

Groundsmaster 4000--D

Page 4 -- 69 Rev. E

Hydraulic System (Rev. B)

| Categories | Lawn Mower Manual, Toro Lawn Mower Manual |

|---|---|

| Tags | Toro Groundsmaster 4000 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)