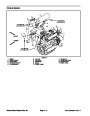

Reassembly

11.Dip idler gear (21) in clean hydraulic oil and install in

gear pocket of middle body.

It is important that the relationship of the backplate,

adapter plates, bodies, wear plates and front plate is

correct. The two half moon cavities in the bodies must

face away from the front plate or adapter plate. The

smaller half moon port cavity must be on the pressure

side of the pump. The side of the wear plate with mid

section cutoutmustbe onsuction sideofpump.Suction

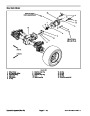

side ofbackplate or adapter plate is always the side with

larger port boss.

12.Install rearadapterplate(24)inplaceonmiddlebody

(19). Check positioning mark on all sections of pump.

13.Position

rear body (26) onto rear adapter plate (24).

Place wear plate (12) into the gear pocket with the pres-

sure seal and backup gasket against the rear adapter

plate.

14.Install

key (22) in slot of drive gear shaft. Dip slip fit

gear(20)incleanhydraulicoilandslideonshaftandinto

gear pocket of rear body (26). Check key for proper

alignment.

1.

Replace the wear plates, pressure seals, backup

gaskets, shaft seal and o--rings as new parts. During re-

assembly, check the scribe mark on each part to make

sure the parts are properly aligned.

15.Dip

rear idler gear (25) in clean hydraulic oil and

install in gear pocket of rear body.

2.

Install o--rings (4) in groove of front plate (15), adapt-

er plates (23, 24), and backplate (27) with a small

amount of petroleum jelly to hold in place.

16.Position

in body are engaged.

backplate (27) over shafts until dowel pins

3.

(14)

middle of the backup gasket must face away from the

wear plate inside the seal.

Install new pressure seals (13) and backup gaskets

into new wear plates (12). The flat section in the

17.Secure

Torque cap screws evenly in a crisscross pattern from

pump components with cap screws (3).

25

to 28 ft--Ib (34 to 38 N--m).

18.Place

ally oil shaft seal (1) and install over drive shaft carefully

so that rubber sealing lips are not cut.

washer(2)overdriveshaftintohousing.Liber-

4.

5.

Place plug (8) into pocket of front plate (15).

Applyathincoatofpetroleumjellytobothmilledgear

pockets of front body (10). Position body onto frontplate

with half moon port cavities in body facing away

from front plate.

19.Place

shaftseal.200in.(5.08mm)belowsurfaceoffrontplate.

1--3/8” O.D. sleeve over shaft and press in

(15)

20.Install

plug(7)andwasher(9)intorearadapterplate.

NOTE: The small half moon port cavity must be on the

pressure side of pump.

21.If

removed, install plug (28) with o--ring into back-

plate and torque from 21 to 24 ft--lb (29 to 33 N--m).

6.

Place wear plate (12) into the gear pocket with the

pressure sealandbackupgasketagainstthefrontplate.

The side with the mid section cut away must be on suc-

tion side of pump.

22.Install

plug from 21 to 24 ft--lb (29 to 33 N--m).

proportional valve (6) into backplate. Torque

7.

Dip drive gear assembly (11) and idler gear assem-

bly (16) into clean hydraulic oil. Slip both gear assem-

blies into gear pocket of front body (10) and into front

plate bushings.

8.

(10).

Install front adapter plate (23) in place on front body

Check positioning marks for correct orientation.

9.

Install middle body (19) onto front adapter plate (23).

Place wear plate (12) into the gear pocket with the pres-

sure seal and backup gasket against the front adapter

plate.

10.Install

key (17) in slot of drive gear shaft. Dip slip fit

gear(18)incleanhydraulicoilandslideonshaftandinto

gear pocket of middle body (19). Check key for proper

alignment.

Hydraulic System (Rev. B)

Page 4 -- 56

Groundsmaster 4000--D

| Categories | Lawn Mower Manual, Toro Lawn Mower Manual |

|---|---|

| Tags | Toro Groundsmaster 4000 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)