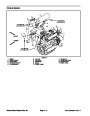

Blade Spindle Service

Disassembly

1

3

2

1.

Park machine on a level surface, lower cutting units,

stop engine, engage parking brake, and remove key

from the ignition switch.

130

(176

to 150 ft−lb

to 203 N−m)

2.

idler pulley to release belt tension. Remove drive belt

from spindle to be serviced.

Remove belt covers from top of cutting deck. Loosen

4

6

7

5

3.

If drive spindle is to be serviced, remove hydraulic

motor from cutting deck (see Cutting Deck Motor Re-

moval in the Service and Repairs Section of Chapter 4

8

9

10

11

12

−

Hydraulic Systems).

7

4.

Start the engine and raise the cutting unit. Stop en-

gine and remove key from the ignition switch. Latch or

block up the cutting unit so it cannot fall accidentally.

Front deck can be tilted for spindle service (see Opera-

tor’s Manual).

13

14

15

85

to 110 ft−lb

5.

Remove cutting blade, anti−scalp cup and bolt from

(115 to 149 N−m)

spindle to be serviced (see Operator’s Manual).

16

17

6.

For drive spindle assemblies (Fig. 8), remove flange

head screws that secure spindle to deck. Remove

spindle housing assembly with motor mount from deck.

Figure 8

1.

2.

3.

4.

5.

6.

7.

8.

9.

Lock nut

Washer

10. Spindle housing

11. Grease fitting

12. Flange head screw

13. Spacer

7.

For driven spindle assemblies, remove flange head

Pulley (drive shown)

V−ring seal (if equipped)

Motor mount

screws and lock nuts that secure spindle to deck. Re-

move spindle housing assembly from the deck.

14. Spindle shaft

O−ring (if equipped)

Oil seal

Bearing set

15. Blade

16. Anti−scalp cup

17. Blade bolt

NOTE: Early production spindle assemblies included a

v−ring seal which has been found to be unnecessary.

Discard v−ring seal if found in spindle assembly.

Spacer set (2 piece)

8.

Loosen and remove lock nut from top of spindle

1

shaft. Remove washer, pulley, and v−ring seal (if

equipped) from spindle. For drive spindle, remove motor

mount.

4

2

9.

Remove the spindle shaft from the spindle housing

which may require the use of an arbor press. The spacer

should remain on the spindle shaft as the shaft is being

removed.

5

3

1

10.Remove

seals from spindle housing.

11.

Allow the bearings, inner spacer and spacer ring to

drop out of the spindle housing.

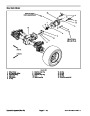

Figure 9

1.

2.

3.

Bearing

Spacer ring

Large snap ring

4.

5.

Inner spacer

Outer spacer

12.Using

cups out of the spindle housing. Remove the large outer

spacer from the housing.

a punch and hammer, drive both of the bearing

13.The

large snap ring can remain inside the spindle

housing. Removal of snap ring is very difficult.

Cutting Units

Page 8 − 10 Rev. E

Groundsmaster 4000−D

| Categories | Lawn Mower Manual, Toro Lawn Mower Manual |

|---|---|

| Tags | Toro Groundsmaster 4000 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)