3.

4.

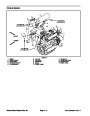

Inspect camplate assembly:

3

A. Thefinishonthepistonshoesurfacesofthecam-

plate (11) should show no signs of scoring.

2

1

B. Inspect camplate (11) bushing surface for wear.

Also inspect surface for coating transfer from bush-

ing.

4

Inspect bushing (44) for contamination embedment

5

within coating of bushing surface coming in contact with

camplate (11).

Figure 45

4.

5.

5.

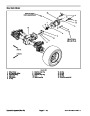

Inspect rotating kit (Fig. 45):

1.

2.

3.

Piston assemblies

Spider

Spider pivot

Piston block

Retainer

A. The pistons should move freely in the rotating kit

piston block bore. If they are sticky in the bore, ex-

amine the bore for scoring or contamination.

.500

(12.7

inch

mm)

B. Examine the O.D. of the pistons for finish condi-

tion. They should not show wear or deep scratches.

Inspect the shoes for a snug fit on the ball end of the

pistons and a flat smooth surface that comes in con-

tact with the camplate. Do not lap piston shoes.

Right Side

Left Side

C. Examine the spider for wear in the pivot area.

D. Examine the spider pivot to insure smoothness

and no signs of wear.

Front flange -- Drive shaft end of pump

Adjust to center piston

Install servo piston

in this direction

Reassembly

1.

lubricated with clean hydraulic oil before reassembly.

All parts should be cleaned and internal pump parts

Figure 46

5.

(1)

Install new sealwasher (4),washer (29),and jamnut

to servo piston bolt. Holding servo piston bolt with

2.

to dimension shown in Figure 44 with the numbered end

of bearing outward.

If necessary, press new bearing into pump housing

hexkeywrench,torquejamnutfrom150to160in--lb(17

to 18 N--m). Check the centering of servo piston assem-

bly (7). Install new cover plate gasket (33) and cover

plate (9) to open side of servo piston and retain with four

washers (31) and socket head screws (5). Torque

screws from 40 to 48 in--lb (4.5 to 5.4 N--m).

3.

servo piston cavity of pump housing (19).

Installthetwonewsealsub--assemblies(37)intothe

4.

Screw the cover plate (10) onto the servo piston as-

sembly (7). Install new cover plate gasket (33) in place

on pump housing. Install servo piston assembly (7) and

cover plate (10) into servo piston bore in right side of

housing (Fig. 46). Retain cover plate with four washers

6.

bushing (44) onto cradle with button head cap screw

(43).

(1.6

Press dowel bushings (40) into cradle and secure

Torque button head cap screw from 14 to 16 in--lb

to 1.8 N--m).

(31)

andsocketheadscrews (5).Torquescrews from40

to 48 in--lb (4.5 to 5.4 N--m). To obtain neutral, centering

the servo piston assembly is required. Measure in from

the left side and set servo piston .500 in. (12.7 mm) from

surface of housing servo bore as shown in Figure 46.

7.

Place cradle sub--assembly (41) into housing (19)

making sure dowel bushings (40) and cradle (41) are

completely seated into housing. Retain cradle sub--as-

sembly with two cap screws (42) after applying Loctite

#277

screws from 25 to 28 ft--lb (34 to 38 N--m).

(or equivalent) to the end of threads. Torque cap

NOTE: Re--adjustment may be required for neutral at

unit start--up.

Hydraulic System (Rev. B)

Page 4 -- 62

Groundsmaster 4000--D

| Categories | Lawn Mower Manual, Toro Lawn Mower Manual |

|---|---|

| Tags | Toro Groundsmaster 4000 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)