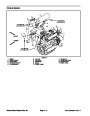

Coupling Disassembly

Remove adapter plate, spring coupling, and cou-

1.

pling spacer from engine using Figure 9 as a guide.

4

3

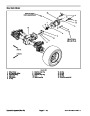

Coupling Assembly

2

1.

Position coupling spacer to engine and align mount-

ing holes. Use two shoulder bolts and lockwashers in the

positions shown in Figure 15 to secure the spacer to the

half threaded holes in engine flywheel. Torque shoulder

bolts from 10 to 12 ft−lb (13.6 to 16.3 N−m).

2

3

4

2.

Install four cap screws and lockwashers to coupling

spacer and flywheel. Torque cap screws from 17 to 21

ft−lb (23 to 28.5 N−m).

1

3.

Place dowels in locating holes of coupling spacer

(Fig. 15).

Figure 15

4.

Position spring center coupling (coil springs toward

1.

2.

Coupling spacer

Shoulder bolt position

3.

4.

Cap screw position

Dowel position

engine (Fig. 16)) over dowels. Secure coupling to cou-

pling spacer with cap screws and lockwashers. Torque

cap screws from 35 to 43 ft−lb (47.5 to 58.3 N−m).

5.

Install plate pins into engine casting. Position pump

Hydraulic

Pump Side

Engine Side

adaptor plate to engine using plate pins as alignment

points. Secure adaptor plate with cap screws and lock

washers using a star pattern tightening procedure.

Engine Installation

1.

If removed, install engine mount brackets to the en-

gine using Figure 9 as a guide.

Spring Center

Coupling

2.

Connect hoist or lift to the front and rear lift tabs on

engine.

Figure 16

Install coolant reservoir bracket and reservoir to fan

3.

Position fan shroud around the engine fan.

7.

shroud.

CAUTION

8.

Connect throttle cable to the speed control lever with

washer and lock nut. Install cable to mounting bracket

(Fig. 11). Adjust throttle cable (see Operator’s Manual).

One person should operate lift or hoist while the

other person guides the engine into the machine.

9.

Connect fuel line to the injection pump (Fig. 11).

IMPORTANT: Make sure not to damage the engine,

fuel and hydraulic lines, electrical harness, or other

parts while installing the engine.

10.Install

plate.

traction cylinder assembly to engine adapter

4.

5.

Slowly lower engine into the machine.

IMPORTANT: Support hydraulic pump assembly to

prevent it from falling and being damaged.

Align engine to the rubber engine mounts and secure

with cap screws, rebound washers, and flange head

locking nuts.

11.

Pump Assembly in Chapter 4 − Hydraulic Systems).

Install hydraulic pump assembly to engine (see

6.

Secure fan shroud to the radiator with four cap

12.Connect

pump.

two wires to neutral switch on traction

screws, flat washers, and locknuts. Make sure that

clearance between shroud and fan is at least .180” (4.6

mm) at all points.

13.Connect wires and/or electrical connections to the

Page 3 − 17 Kubota Diesel Engine (Rev. B)

Groundsmaster 4000−D

| Categories | Lawn Mower Manual, Toro Lawn Mower Manual |

|---|---|

| Tags | Toro Groundsmaster 4000 D |

| Download File |

|

| Document Type | Service Manual |

| Language | English |

| Document File Type | |

| Publisher | toro.com |

| Wikipedia's Page | Toro Company |

| Copyright | Attribution Non-commercial |

(0 votes, average: 0 out of 5)